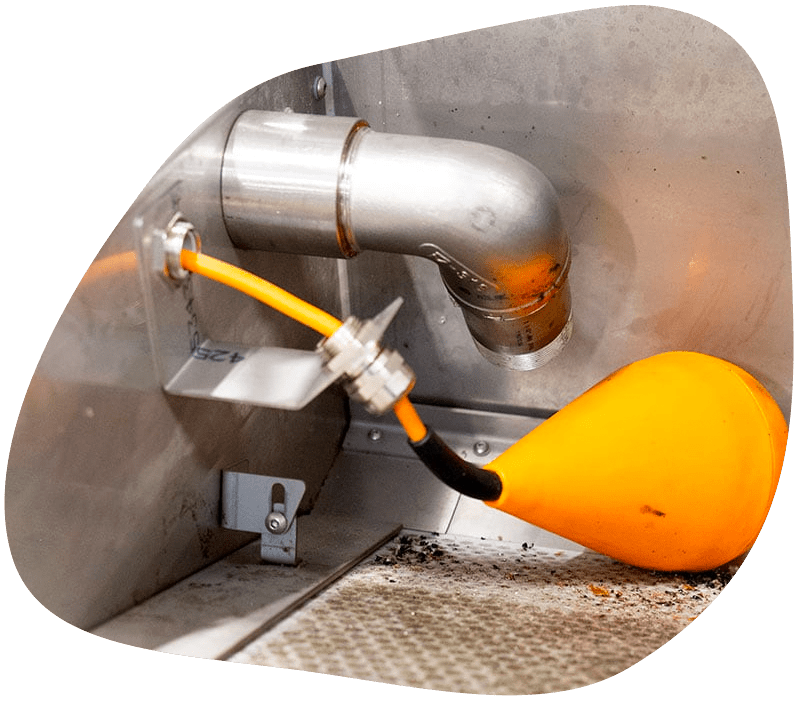

Oil separator

Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

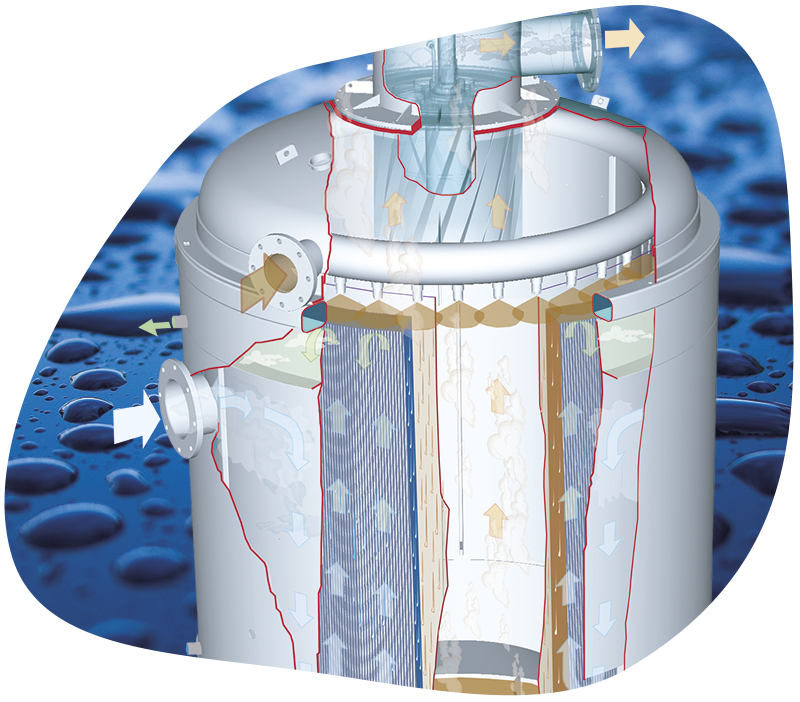

Reverse osmosis

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Magnetic Separator

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Evaporator

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

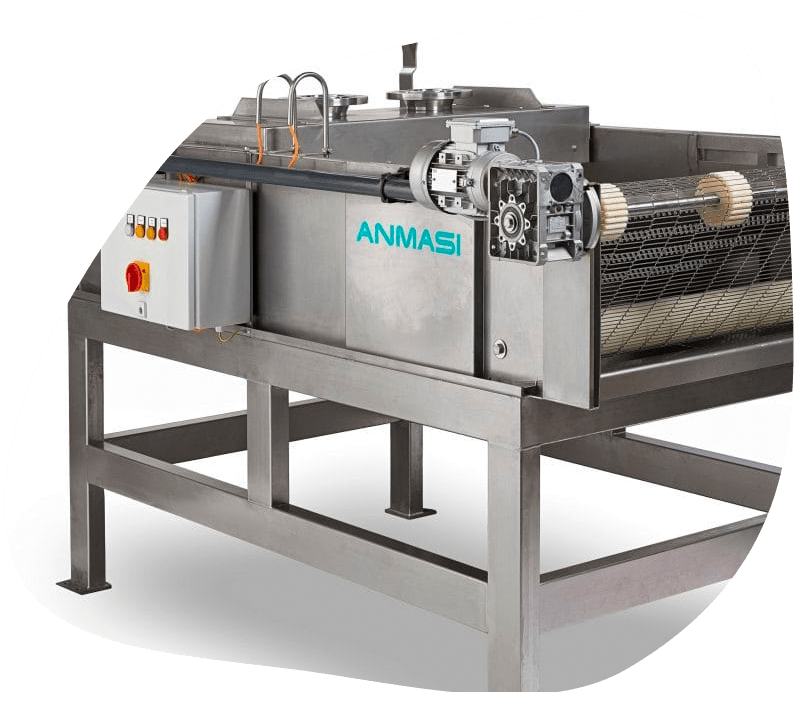

Filtration systems

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Ultrafiltration

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Oil separator

Reverse osmosis

Magnetic Separator

Evaporator

Filtration systems

Ultrafiltration

Filter systems and water treatment

You improve your company's environmental profile by having a filtration system that is adapted to your company's production. A filtration plant is a closed system. Both safety and the working environment are significantly improved because the employees do not have to fill liquids manually.

Filtration facility

If you would like to ensure a sensible operation of your company, it would be a good idea to have filter systems and water treatment installed as a supplement to the washing and cleaning system that you have in your company. The right filtering helps to create a better working environment, better CSR and some lower operating costs in production.

With the correct filtration system, dirt, grime and residues from lubricants and process fluids are removed and then reused again and again, without damaging tools and production equipment. It offers a lot of advantages of both a safety and financial nature for your virksomhed.

With the correct filtration system, dirt, grime and residues from lubricants and process fluids are removed and then reused again and again, without damaging tools and production equipment. It offers a lot of advantages of both a safety and financial nature for your virksomhed.

Filter systems

By filtering and recycling both lubricants and process fluids, you can achieve very low operating costs because the costs of new fluids and disposal are significantly reduced. The filtration also contributes to the fact that the maintenance and replacement of production equipment and tools is significantly reduced, as it is not exposed to the same wear and tear when it is not in contact with liquids containing graphite, magnetic particles, metal shavings or other things.

With a high-quality filtration system, oil and grease can also be removed from water, so bacterial growth is prevented, and dust, paint, resin, hair and small particles can be removed.

With a high-quality filtration system, oil and grease can also be removed from water, so bacterial growth is prevented, and dust, paint, resin, hair and small particles can be removed.

Good for the environment

You improve your company’s environmental profile by having a filtration system that is adapted to your company’s production. A filtration plant is a closed system. Both safety and the working environment are significantly improved because the employees do not have to fill liquids manually. And lubricants and process fluids are recycled instead of constantly having to be replaced.

You can get our filter system with a magnetic separator so that iron oxides, graphite and other magnetic particles are removed. And the system quickly and effectively removes dirt such as sand, dust, paint, hair, resin and other small solid particles down to 5 microns.

You can get our filter system with a magnetic separator so that iron oxides, graphite and other magnetic particles are removed. And the system quickly and effectively removes dirt such as sand, dust, paint, hair, resin and other small solid particles down to 5 microns.

Metal and plastic shavings

Our filter system removes metal and plastic shavings, which extends the service life of the process fluid and reduces wear and tear on tools.

Oil and fats

Effectively removes demulsifying oils and fats which extend the life of the process fluid and reduce the risk of bacteria formation.

Magnetic particles and graphite

Our filter system is available with a magnetic separator to remove graphite, iron oxides and other magnetic particles.

Solid particles and dirt

Effectively removes dirt such as dust, sand, paint, hair, resin and similar solid particles down to 5 microns.