Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

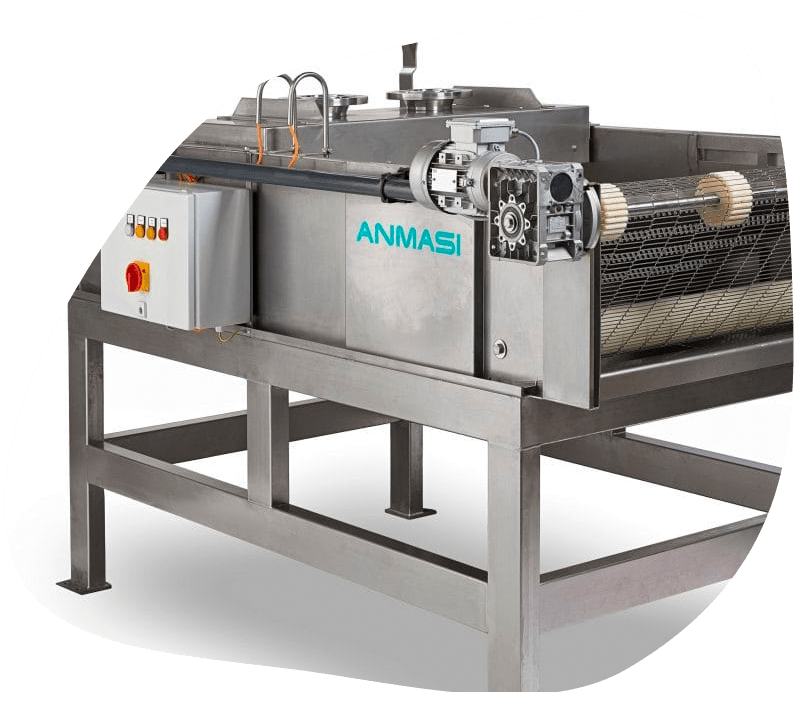

Bandfilter TM

Our bandfilter is produced in Denmark and developed for continuous filtration of process fluids and oil where the strain on the filter paper is constant and high.

This type of bandfilter, with it’s unique construction where the filter paper is advanced with a moter-driven belt conveyor, con filter up to 3000 l/minute depending on the process liquid. It is supplied in strong stainless consctruction with level sensor, electric control and filter paper, and it is available in 6 sizes depending on the task.

Applications:

| Additional options:

|

- WastewaterOur filter systems are used for the treatment of waste water in the municipal sector and are ideal for pre-treatment of waste water and process fluids before ultrafiltration etc.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

Produced with a stainless-steel frame, cabinet and conveyor which makes it ideal for most applications.

The bandfilter has easy and quick operation of various functions via rotary knobs.

The hydrostatic band filter is produced in accordance with the European Machine Directive.

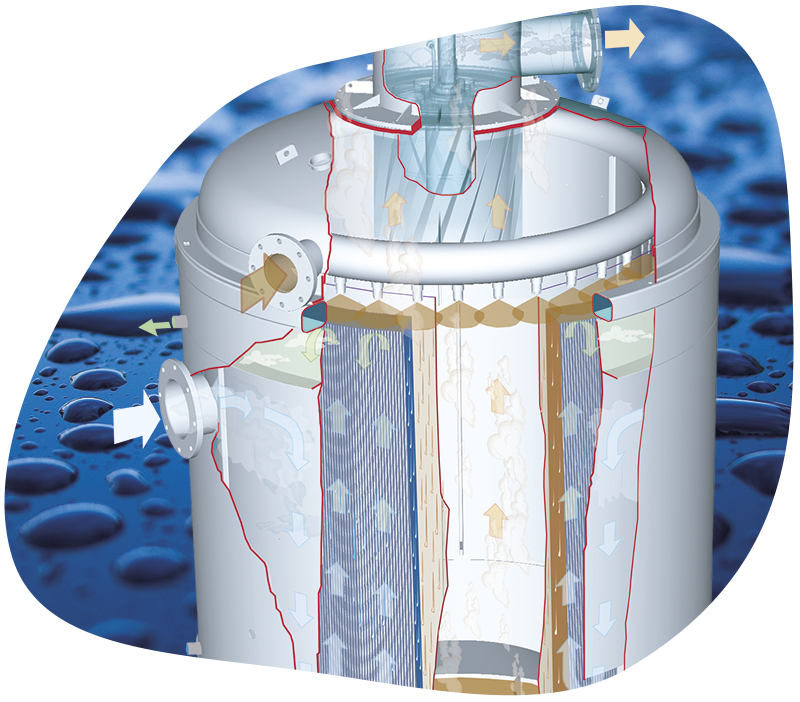

The deep-bed construction makes it possible to have a high liquid level and thoroughly and its specially designed chain-conveyor construction lowers filter consumption and thickness.

Its with chain-conveyor construction which means we are carrying the filter paper instead of pulling it which makes it able to operate with high volume and heavy-duty contaminants.

Its with integrated overflow channel to avoid the process fluids reaching a too high level

Secures reliable distribution of the process fluids inside the bandfilter.

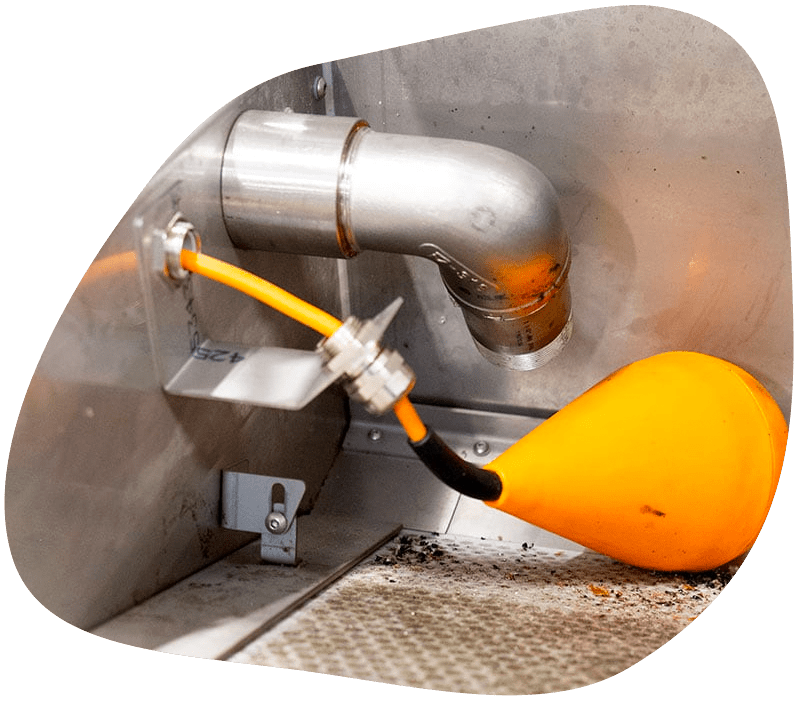

The electrical level sensor ensures automatic supply of filterpaper during the process.

With the right filter paper, our belt filter can remove particles down to 5 microns.

Technical data

| Model | TM 40 | TM 80 | TM 180 | TM 240 | TM 360 | TM 550 |

| Flow capacity | 216 l/min | 450 l/min | 1000 l/min | 1500 l/min | 2000 l/min | 3000 l/min |

| Protection grade | IP 54 | IP 54 | IP 54 | IP 54 | IP 54 | IP 54 |

| Control voltage | 24 VDC | 24 VDC | 24 VDC | 24 VDC | 24 VDC | 24 VDC |

| Power supply | 3×230/400V – 50 hz. | 3×230/400V –50 hz. | 3×230/400V – 50 hz. | 3×230/400V – 50 hz. | 3×230/400V – 50 hz. | 3×230/400V – 50 hz. |

| Filter width | 500 mm | 500 mm | 1000 mm | 1000 mm | 1500 mm | 1500 mm |

| Filter areal | 0,4 m2 | 0,8 m2 | 1,8 m2 | 2,4 m2 | 3,6 m2 | 5,5 m2 |