Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

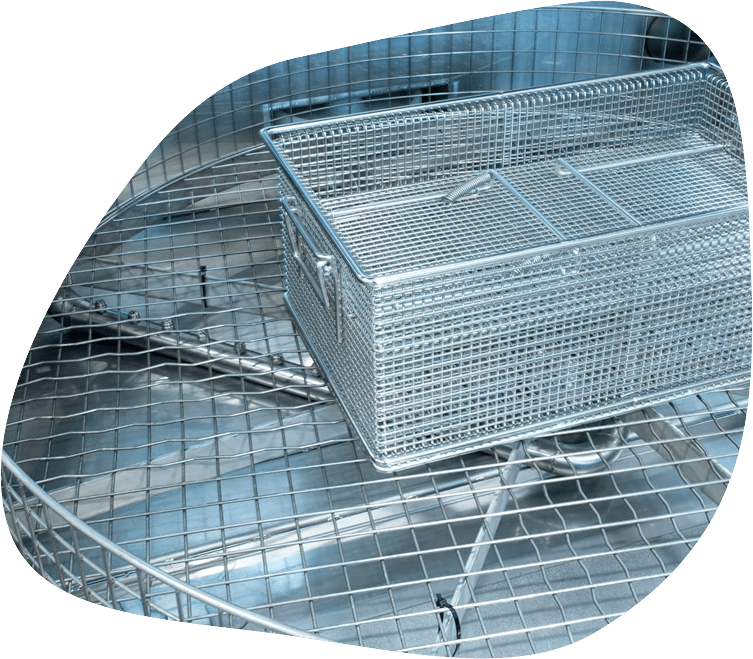

Alcohol washers

High quality, energy-friendly and meets even the strictest cleanliness requirements

Discover some of the market’s most efficient and energy-frindly alcohol washers, which are offered both as standard and special systems.

We offer washing plants for modified alcohol and hydrocarbons from IFP Europe, which is among the leading manufacturers in the world. More than 200 alcohol washers are delivered per year from their factory in Northern Italy, and the hallmark of all facilies is the high quality and sustainable profile.

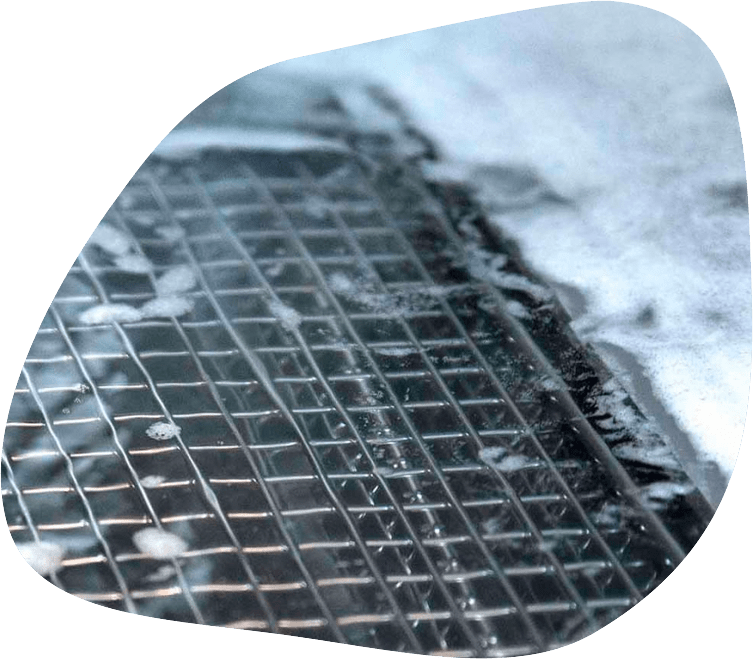

Vacuum-based technology

Since the entire washing process takes place under vacuum, you will as a customer experience a wide range of advantages both in relation to energy consumption and the quality of the finished items.

Uniform washing result

One of the biggest advantages of the alcohol system is their consistent washing results around the clock! Because the modified alcohol is constantly distilled in the facility, we ensure that the liquid used to clean the items is always in top form.

Therefore, you will not experience that the washing quality is decreasing over time, as is the case with a water-based washing system. Because as a rule of thimb, the more “dirty” the liquid becomes, the more the cleanliness of the items will decrease.

Short cycle time

When we work under vacuum instead of atmospheric pressure, the cycle time is significantly reduced. This allows us to clean and degrease the items faster, which means that the cycle time is usually halved compared to washing solutions that work under atmospheric pressure

Perfect for degreasing

Because the items in the washing process are rinsed nad submerged under the liquid while the basket is rotated, we have a good mechanical effect. This, combined with the good properties of the modified alcohol, means that we can meet even the strictest cleanliness requirements, regardless of the complexity of the subject.

Effecient drying

When vacuum drying is used, we are absolutely sure that your items will come ou of the machine completely dry! Especially in an alcohol washer, since the modified alcohol has a low boiling point which means it evaporates within a very short time when vacuum drying.

As a result, you will never have to worry about drying, regardless of the complexity of the item!

The right solution for small and complex items

if you work with small items, complex items and similar, then an alcohol washer is the right thing for degreasing. Because an alcohol washer that works under vacuum ensures that all nooks, corners, channels and blind holes are washed thoroughly, whether we are talking about small threaded holes or similar.

Low power consumption

The advantage of an alcohol washer is a very low energy consumption. Large heaters must not be used to heat water as in water-based system. Because alcohol can work at room temperature, and thus we only have to use the heat effect for the ongoing distillation during the washing process.

This means that the power consumption compared to a similar water-based washing soluliton is usually halved or more!

Very low chemical consumption

Because the modified alcohol is continuously distilled in the washing facility, we have an extremely low chemical consumption. During the actual distillation, impurities are effectively separated from the alcohol, this includes oil, cooling lubricants and solid particles which are removed t such an ectent that the alcohol can be resued for many years without having to be replaced

In additon, since we work under total vacuum in the washing facility, where is almost no evaporation of the modified alcohol into the atmosphere, which results in a very low chemical consumption and CO2 footprint.

In an alcohol washer of normal size, around 200 liters of modified alchol are typically used per year.

Minimal service and low operating costs

Although an alcohol washer usually costs more than a similar water-based washing system, it is usually a good investment if you need to degrease objects in baskets. The reason for this is that we have virtually no costs associated with either operation or maintenance.

Please note that the modified alcohol is most often replaced by customers once every 5 years, but it is also seen that customers use the same one for many more years.

Why not always alcohol?

Alcohol cleaners have many advantages, but they are not always the solution. Although they have a low energy consumption and good washing results. For example, it is best suited for degreasing only, whereas water-based solutions are more universal

therefore, always contact us on 76 50 02 32 or info@anmasi.dk for guidance, and we will help you with a solution that suits your needs!

Anvendelsesområder

Olie- og kølesmøremidler

Vores vaskeanlæg fjerner nemt olie- og kølesmøremidler fra bearbejdede emner, og komponenter som skal vedligeholdes. Vi kan rengøre næsten alle overflader af metaller, plastik, kunststof etc.Tidsintervallet i processen varierer, samt hvilken type kemi vi bruger til den enkelte opgave. Det afhænger af hvilke typer af olier- og kølesmøremidler vi arbejder med, fælles for dem alle er at de rengøres i en vandbaseret løsning, som er enten neutral eller mild alkalisk.Hvilken type af vaskeanlæg og metode afhænger af den specifikke opgave, og bestemmes i dialog med kunden.

Rust

Vi fjerner effektivt korrosion med vores neutrale vandbaserede rustfjerner. Den fjerner både nyt- og gammel rust fra eksempelvis reparationsemner, eller flyvrust på komponenter.Alt dette gøres effektivt med vores neutrale produkt, samtidig med at tage hensyn til omgivelser og arbejdsmiljøet.

Maling

Vi har stor erfaring med at fjerne maling fra komponenter. Vi fjerner typisk maling fra malerkroge, fixturer, ophæng, pumper, pistoler og dyser.Fordelen ved et vaskeanlæg til opgaven, er at i får en lukket proces, hvor man undgår manuel rengøring med kraftige kemikalier, som f.eks. fortynder. I stedet får i et vaskeanlæg med vandbaseret malingsfjerner.Vi kan både fjerne flydende- og hærdet maling, som oftest gøres ved hjælp af en ultralydsrenser.

Epoxy

Vi har stor erfaring med at fjerne både hærdet- og ikke-hærdet epoxy fra emner. Hvilket i mange tilfælde er en svær opgave, uden det rette udstyr. Derfor er det vigtigt at have den rette løsning hvad angår både kemi og vaskeanlæg.Fordelen ved vores løsninger, er at de automatisk og miljøvenligt i en vandbaseret løsning fjerner epoxyen, og tager hensyn til arbejdsmiljøet.Vi har igennem de seneste år, udviklet mange specialløsninger for specielt kunder i vindmølleindustrien til dette formål.

ALCOHOL WASHERS

Watch this video with a presentation of the company IFP Europe, which is our partner in washing facilities for modified alcohol and hydrocarbons.

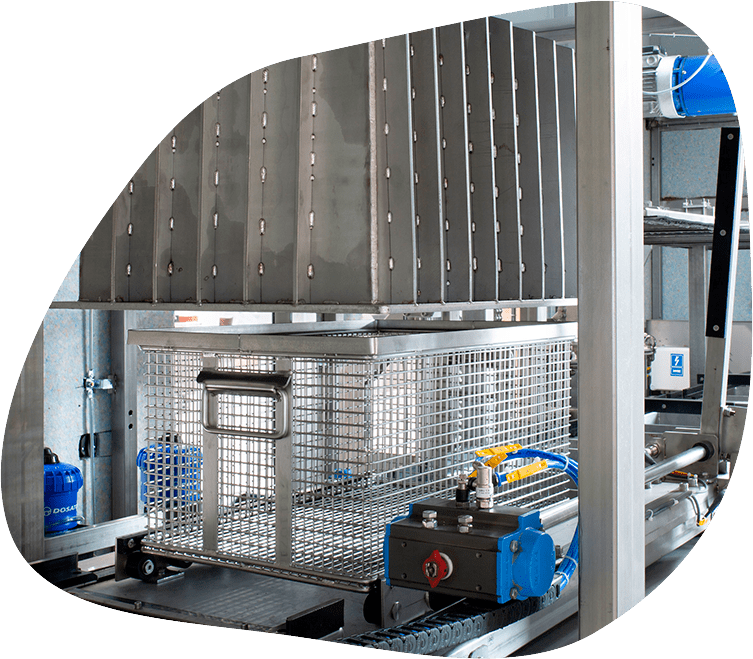

Comes standard with:

- Wash, rinse, vacuum dry

- Cleaning with liquid liquid and steam

- Efficient distiller

- Siemens PLC incl. touch screen