Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

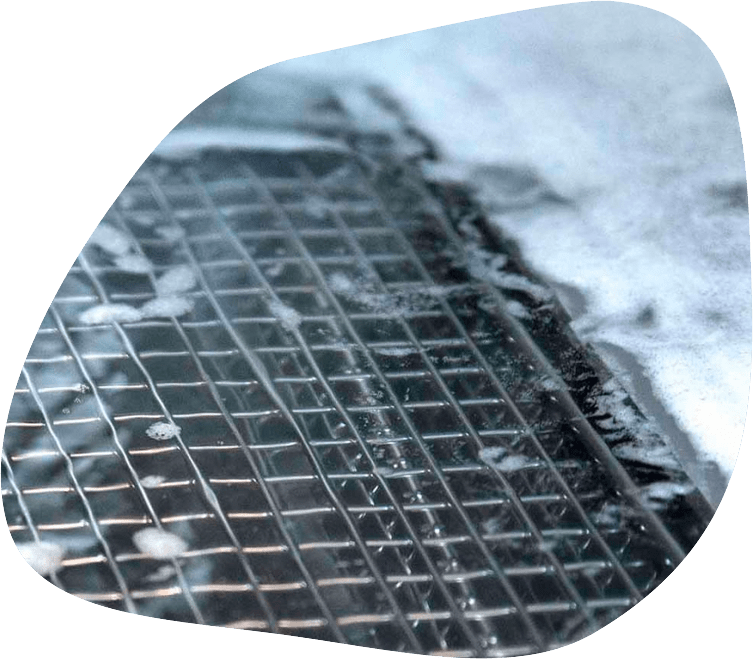

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

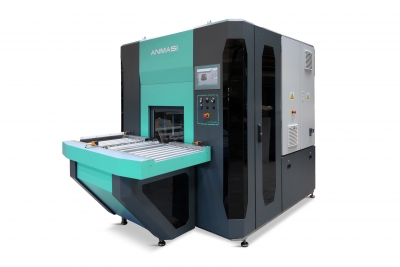

Rotoline ST

Our rotation basket washers meet even the strictest cleanliness requirements for both small and large parts that are complex.

Rotoline ST with it’s unique and compact design is supplied with washing, rinsing and drying, where you have the option of spraying, ultrasonic cleaning, turbulence and hot air or vacuum drying.

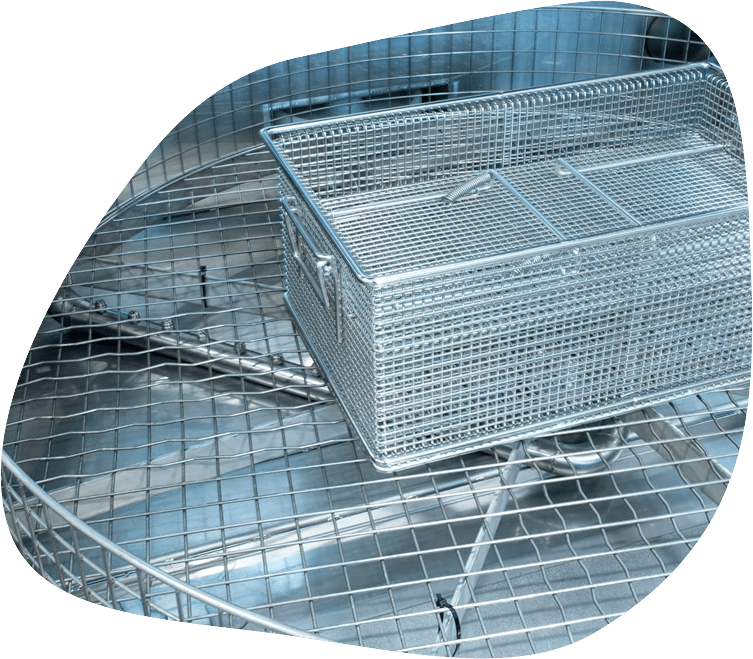

The washing process takes place in a chamber where the basket, with the items, either rotates 360°, tips sideways or stands still during the washing and rinsing process, which is carried out depending on which program is selected.

Standard modules:

| Additional options:

|

Who uses this product?

- The aviation industryThe aviation industry has high cleanliness requirements and, like the car industry, we work with large series where this type of washing system or ultrasonic cleaner is most often the right solution.

- Pharmaceutical industryThe preferred solution for the pharmaceutical industry is our series of ultrasonic cleaners which ensure a gentle and effective cleaning of the item. Depending on the need, these ultrasonic cleaners are available in different sizes and with automation.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

- AutomotiveThis washing plant is very popular for tasks in the automotive industry and has been developed for both large and small production lines, depending on your needs.

Produced with a stainless steel cabinet, tank cover, electrical cabinet, pumps and heating elements.

Control panel Siemens S7-1500 PLC with 7” touchscreen and process visualization.

Rotoline is constructed in a strong frame construction and can standard handle baskets weighing up to 150 kg.

Functional and user-friendly design that is incredibly compact and comes with large tanks.

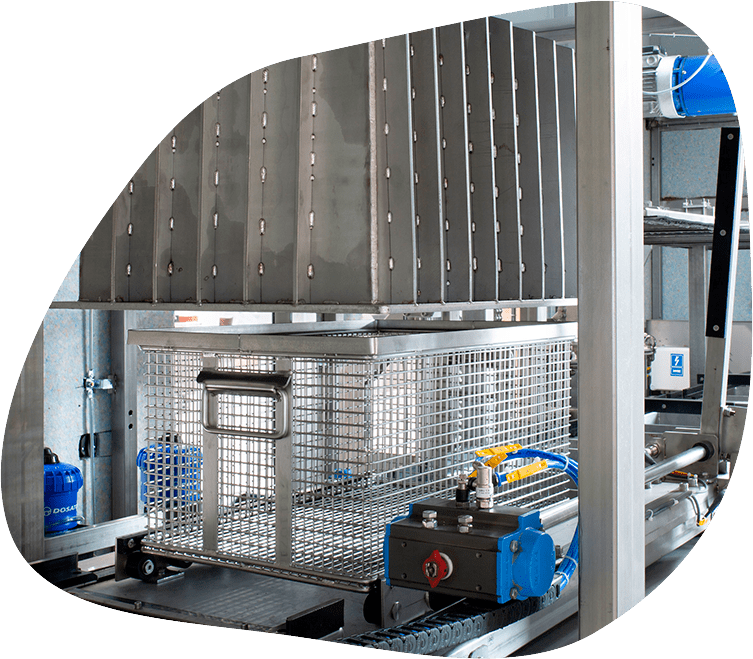

Available as a customized solution with conveyor systems for loading and unloading or robots.

Rotoline is including coarse filters 400 micron in washing and rinsing stages.

Rotoline is with a informativ and well defined alarm system instructing operators how to solve potential issues.

The rotating basket washer complies with the European Machine Directive.

The basket washer has a automatic water filling system, which ensures that there is an optimal liquid level.

Placed on adjustable stainless steel machine feet, and can also be supplied on wheels.

The system includes a fully insulated cabinet which has a thickness between 30-50 mm.

The Rotoline ST is delivered prepared for the installation of ultrasonic transducers, if the customer wishes this subsequently.

Prepared for oil separator, extraction fan, automatic chemical dosing and filtration.

Used for protection of heating elements, ultarsonics and stainless steel pump.

Supplied with adjustable rotation speed, sideways tipping or, if necessary, a stationary basket during the washing process.

| Model | ROTOLINE 530 | ROTOLINE 600 | ROTOLINE 1200 |

| Basket size (LxBxH) | 521x321x200 mm | 600x400x330 mm | 1200x400x330 mm |

| Max. basket weight | 40 kg | 150 kg | 150 kg |

| Basket capacity (each hour) | 3 – 6 | 3 – 6 | 3 – 6 |

| Pump pressure | 2.5 – 3.2 bar | 5 – 10 bar | 5 – 10 bar |

| Pump flow | 250 l/min | 260 – 400 l/min | 260 – 400 l/min |

| Tank volume | 250 L | 750 L | 1100 L |

| Heating effect | 9000 W | 18000 W | 36000 W |

| Temperature | 30 – 70°C | 30 – 70°C | 30 – 70°C |

| Power supply | 35 A | 63 A | 63 A |

| High pressure air | 6 bar | 6 bar | 6 bar |