Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

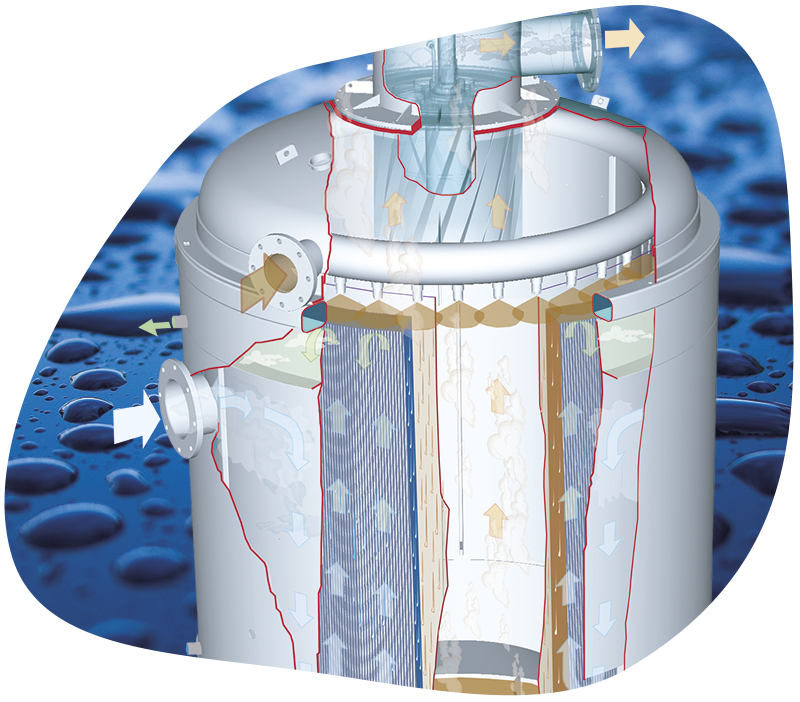

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

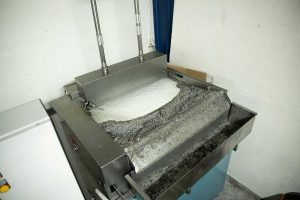

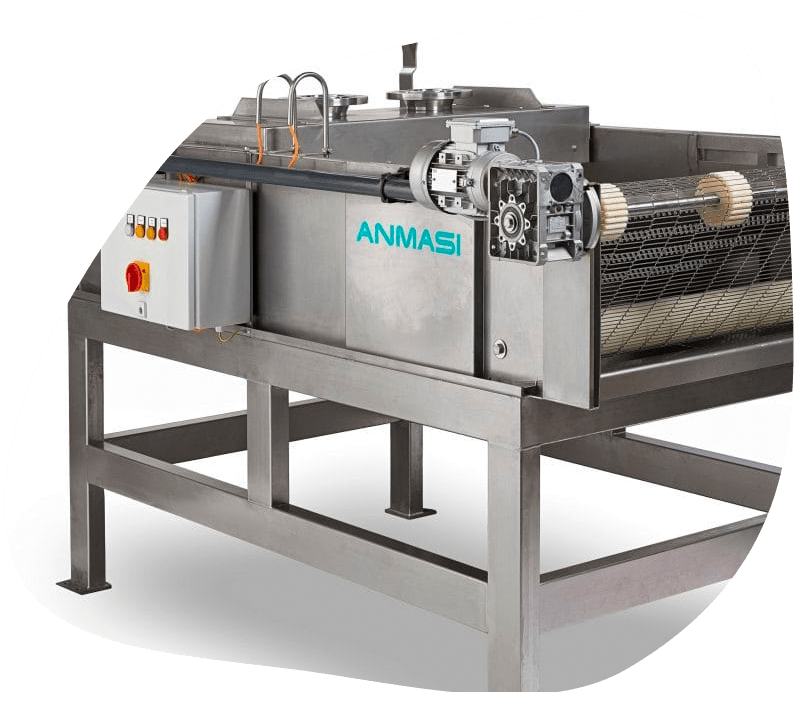

Bandfilter UF

Our most popular stainless bandfilter produced in our own factory in Denmark, and delivered in four sizes depending on need.

It is mainly used for filtering cooling lubricants, oil or process fluid for solid particles and chips. The bandfilter is hydrostatic and has a user-friendly and simple construction that can easily be integrated into exsiting process machines. The band filter’s unique construction and frequency converter ensure that you have constant low consumption of filter paper compared to similar products on the market as we only feed a little paper at a time.

It is supplied with filter paper alarm, dirt tray, inlet box and filter paper ready for installation.

Applications:

| Additional options:

|

See band filter UF in action on this video of a filter system:

- WastewaterOur filter systems are used for the treatment of waste water in the municipal sector and are ideal for pre-treatment of waste water and process fluids before ultrafiltration etc.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

Belt filter produced with stainless housing, dirt tray and paper guide for industry.

With the right filter paper, our belt filter can remove particles down to 5 microns.

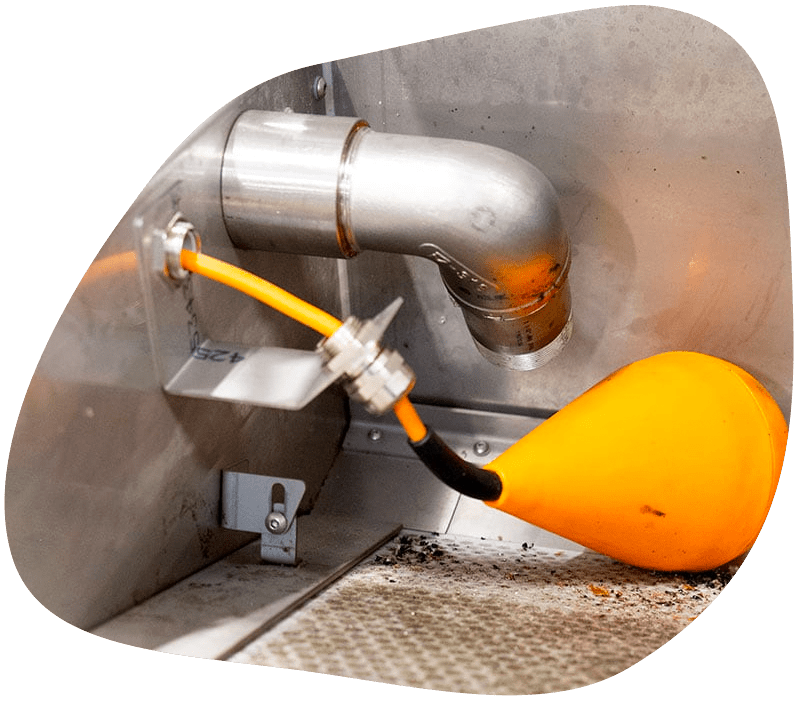

The electrical level sensor ensures automatic supply of filterpaper during the process.

The bandfilter is constructed focusing on low operation cost, which means we exploit the filterpaper completely.

The bandfilter is produced in Denmark in accordance with the European machine directive.

The bandfilter is hydrostatic which means its more efficient and consumes the filterpaper optimal. Which reduced the operation cost and results in better filtration.

Filtrates up to 800 liters of process fluids pr. minute and more depending on customer requirements.

The frequency-regulated gearmotor which is automatic moving the filterpaper, ensures smooth operation and improves filtration.

Build-in overflow channel for safe-guarding against a high fluid level.

Technical data

| Model | UF 500 | UF 1000 | UF 2000 |

| Length | 965 mm | 965 mm | 1965 mm |

| Width | 700 mm | 1200 mm | 1200 mm |

| Inlet height (kaskade) | 538 mm | 538 mm | 657 mm |

| Inlet height (normal) | 480 mm | 480 mm | 599 mm |

| Flow capacity | 150 l/min | 350 l/min | 600 l/min |

| Power supply | 220-240V – 50 hz. | 220-240V – 50 hz. | 220-240V – 50 hz. |

| Control voltage | 24V | 24V | 24V |

| Safety classification | IP 54 | IP 54 | IP 54 |