Anmasi – Washing systems, filter systems and chemical products

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Epoxy remover without the use of strong solvents

We offer solutions designed for the removal of epoxy in various states without the use of strong solvents such as acetone.

CONTACT US AT tEl.: 76 50 02 32 or info@anmasi.dk

One-stop-solution

Design – Develop – Production – Service – Environment

At Anmasi we take great pride in controlling the entire process of designing, manufacturing, installing and servicing your industrial cleaning solution. Our dedicated employees and loyal subcontractors constitute a comprehensive and competent organization focused solely on customer satisfaction. Our own R&D and production facilities deliver the solutions you need, and our service organization keep them up and running. Around the world and around the clock.

We will find the solution

In addition to manufacturing our own standard and custom solutions we also have our own production of filters, and we carry all other necessary parts and accessories in stock. Our in-house experts are always standing by to assist you, whenever you need help. At our lab we are able to test the purity of your subjects to make sure that the desired cleaning solution actually meets your demands.

We got you covered

Our service organization is spread out both nationally and internationally. No matter where you are, and where you need us, we are never far away. Our broad expertise extends across industries, borders and technologies including robot cleaning systems and other advanced solutions.

Watch the video to understand how we collaborate with our customers!

How Anmasi A/S starts a new project and finds solution to the task.

PROCESSERNE

SPRAYING

ULTRASOUND

TURBULENCE

RINSE TANK

OSCILLATION TANK

HOT AIR DRYING

VACUUM DRYING

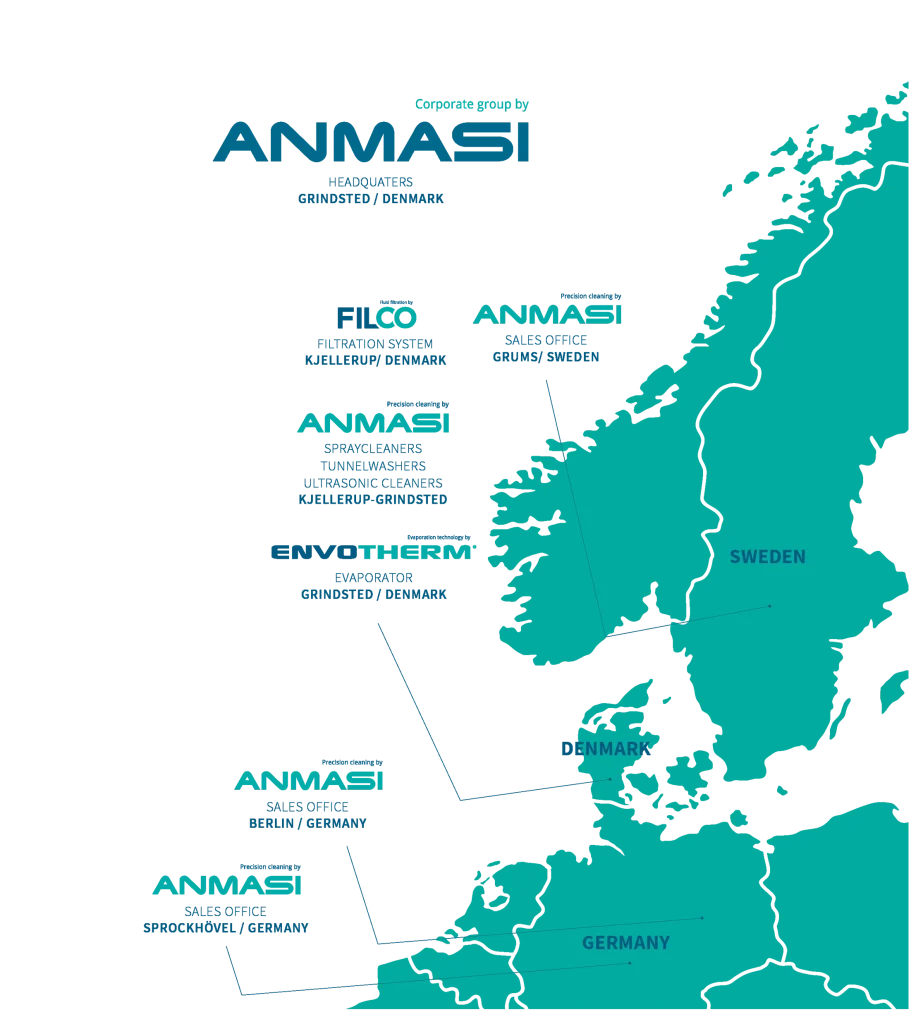

Anmasi was founded by Jan Hedeby Sørensen, who started in 1989 with the production of industrial washing and cleaning technologies.

The company’s fundamental purpose was to create environmentally friendly solutions, which has meant the production and supply of more than 2.000 cleaning- and filtration systems delivered worldwide

In 2012, we started our product program with ultrasonic cleaners, spraywashers and chemical and then in 2016 we expanded with filtration solution after taking over a Danish company specialized in this.

Again in 2022 we expanded with production of evaporation plants when purchasing the company Envotherm Solutions.

Today, Anmasi Group consists of three production companies, Anmasi A/S, Filco ApS, Envotherm Solution A/S and sales company in Germany Anmasi GmbH.

Jan Hedeby Sørensen, CEO

News

- Gjuteriteknik L Abrahamsson AB Invests in Cleanliness with Equipment from ANMASI15/10/2024

- Come and visit us at the AMB trade fair in Stuttgart04/09/2024

- 60 washing machines and ultrasonic cleaners for the defense forces21/05/2024

- Large tunnel washer delivered to California26/04/2024

- The production of Envotherm in Grindsted is now in full swing17/04/2024

- Production of new silent ultrasonic cleaner10/04/2024

- Great interest at the exhibition in Gothenburg26/03/2024

- ENVOTHERM SOLUTION is moving to new production facilities.07/03/2024

- New washing system at Ortlinghaus!21/02/2024

- Come and visit us at the NORTEC trade fair in Hamburg24/01/2024

Combiline

Our most popular range of ultrasonic cleaners for industry, which can be offered in many different sizes, modules, and a wide selection of accessories. The solution is always individually adapted to the customer's needs and can be supplied with a filter system, oil separator etc.

Rotoline

Extremely robust washing system with rotating basket that is tailored to the customer's needs and offered in modules or as a single-stage washing system. Developed for complex items with high cleanliness requirements.

Frontloader AFP

These are our robust sinks suitable for heavy items. It is supplied with a pneumatic front door and is produced both as a standard and special plant in Denmark.

Masterclean

Anmasi's customized central plant produced in stainless steel for filtering coolants and lubricants, oil and process fluids.

Maxiline

This is our in-line ultrasonic cleaner with multiple tanks and automatic handling, which is tailored to the customer's needs. Our solution is very robust and is therefore suitable for both large and small items that need to be washed around the clock.

Our solutions are based on many years of experience and are tailored to the customer's needs, regardless of whether we are talking about a standard or special solution

Anmasi Group

Anmasi A/S – Filco Aps – Envotherm Solution A/S

Anmasi Groups mission is to be as close to the customer’s needs as possible. Anmasi Group covers, as an umbrella organisation, three companies: ANMASI, FILCO and Envotherm.

We offer solutions for industrial cleaning and recycling of process fluids in, among other things the metal and plastics industry – each company with its own specialty within this;

ANMASI supplies total solutions for industrial washing plants, FILCO supplies filtration technology and Envotherm supplies evaporation technology for the recycling of liquids. Envotherm Solution A/S is ISO 9001 certified.

With the environment in mind!