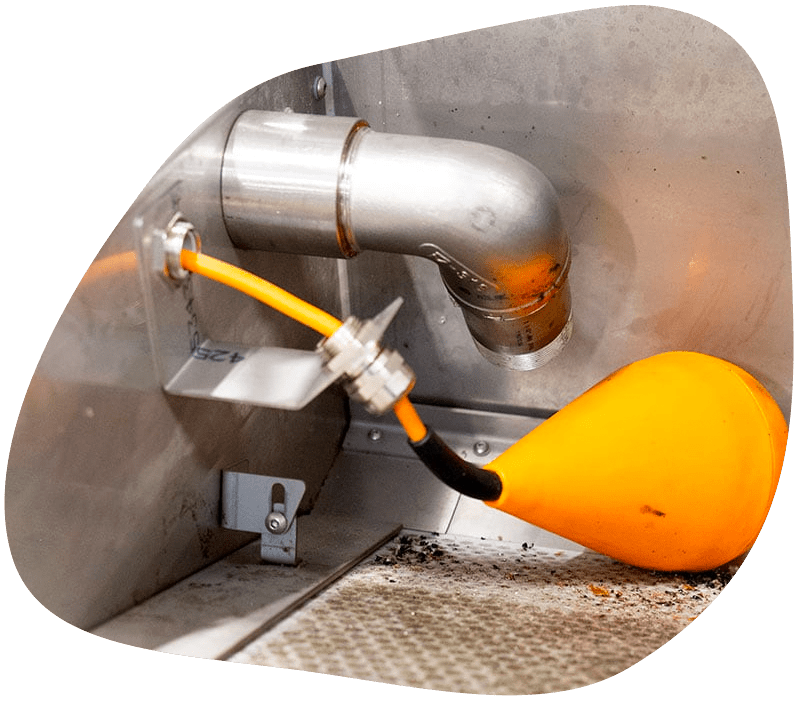

Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

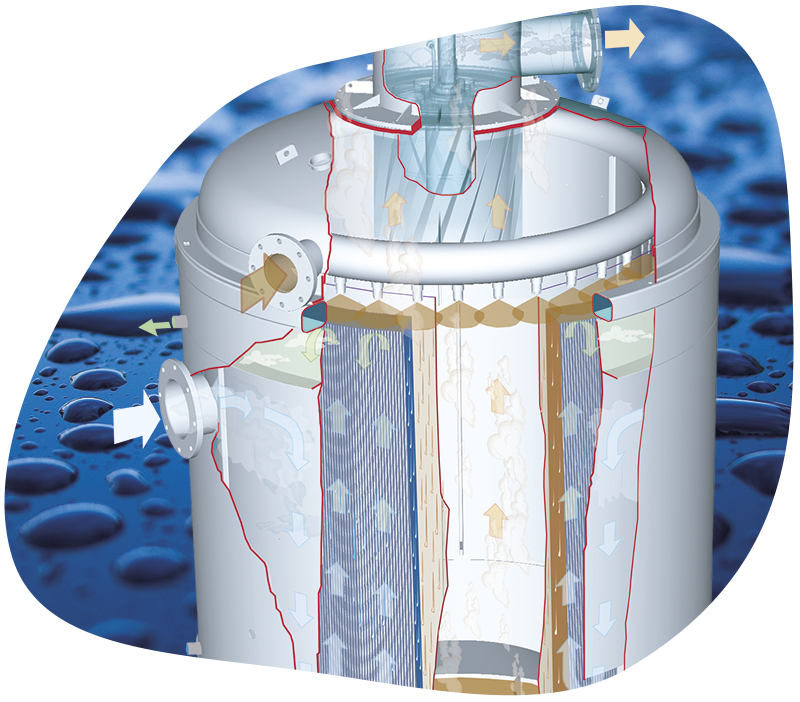

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

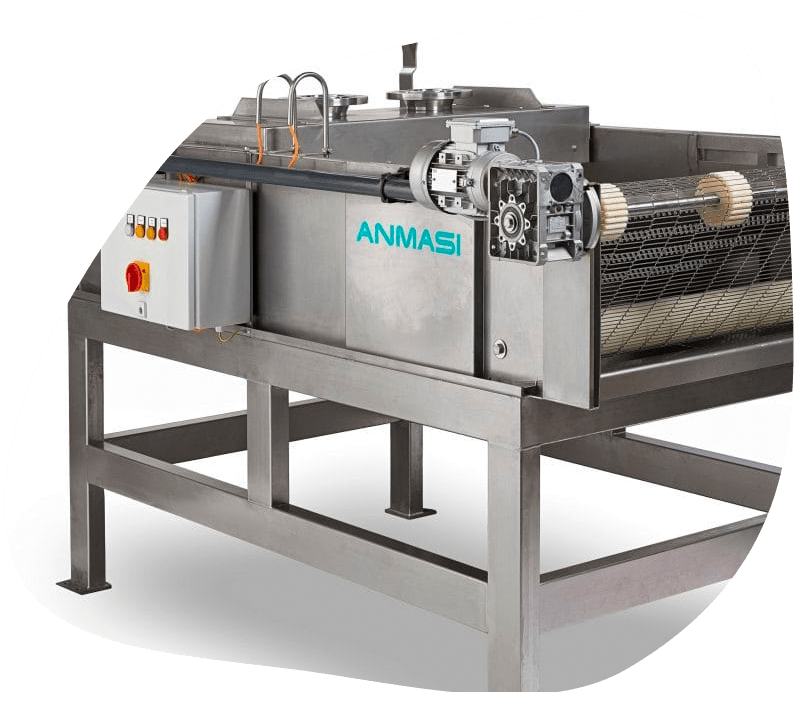

Masterclean systems

Reduce your operating costs significantly, extend the life of your tools nad protect the enviromment with a central filtration system from us.

Our tailor-made central filtration systems for efficient filtration of lubricants and process fluids made at our factory in Denmark.Its available either as a part- or full flow system constructed in powerful stainless steel with badfilter, oil separator, pumps, level control, automatic dosing and touchscreen. This is a complete solution with user-friendly controls including monitoring and alarms as well as the possibility of SMS warning and a wide range of extra options

Applications:

| Additional options:

|

- WastewaterOur filter systems are used for the treatment of waste water in the municipal sector and are ideal for pre-treatment of waste water and process fluids before ultrafiltration etc.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

Central system produced in stainless construction with lacquered electrical cabinet.

Reduce your costs with less time spent refilling processing machines.

Effective filtering of the process liquid down to 5 microns with a bandfilter that has an incredibly low consumption of filter paper.

Central systems are available as a standard solution or tailored to your needs.

The electrical level sensor ensures automatic supply of filterpaper during the process.

The bandfilter is designed with a focus on low operating costs and therefore we always use the entire filter cloth with the unique construction.

The hydrostatic band filter is produced in accordance with the European Machine Directive.

The filtration system is automatically controlling the waterlevel using a level sensor and magnetic valves.

The centralized filtration systems is delivered with complete monitoring systems including alarms and possibility for SMS-service.

Safety protection of components such as pumps on the machine.

The central system is prepared for stainless filter housing, cooling system, magnetic separator and automatic dosing.

Central plants are supplied with part-flow where you have the option of using processing machines without filter plants if necessary.

Anmasi offers complete delivery and installation with its own fitters who are your guarantee that the equipment is installed correctly.

We offer central plants that can feed more than 35 processing machines at the same time as standard.

Technical data

| Model | MC 2000 | MC 3000 | MC 4500 | MC 8000 | MC 10000 | MC 12000 | MC 14000 |

| Tank volume | 2000 l | 3000 l | 4500 l | 8000 l | 10.000 l | 12.000 l | 14.000 l |

| Bandfilter | UF 1000 | UF 1000 | UF 1000 | UF 2000 | UF 2000 | UF 2000 | UF 2000 |

| Oil separator | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time | OS-Q2 / 180 l/time |

| Power supply | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. | 3×230/400V, 50 hz. |

| Control | Analog | Analog | Analog | PLC or computer | PLC or computer | PLC or computer | PLC or computer |

| Labyrinth-system | — | — | — | Yes | Yes | Yes | Yes |