Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

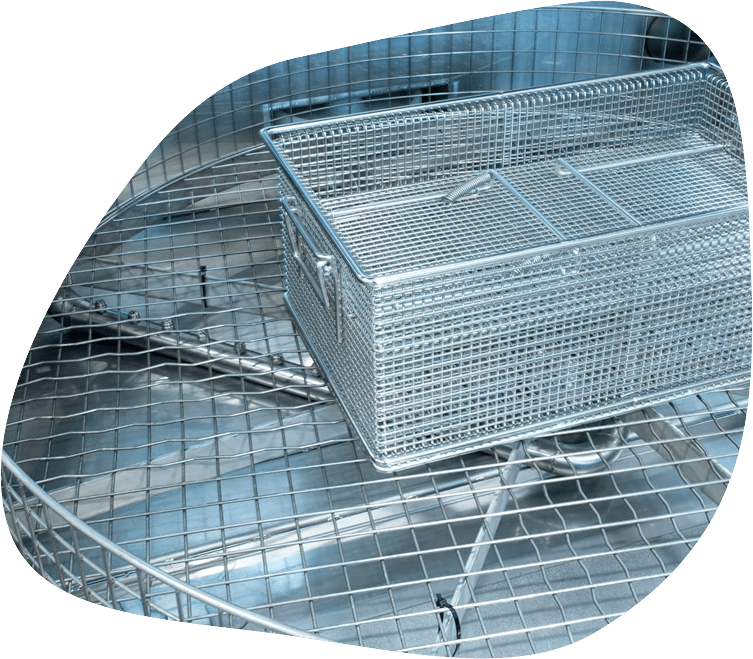

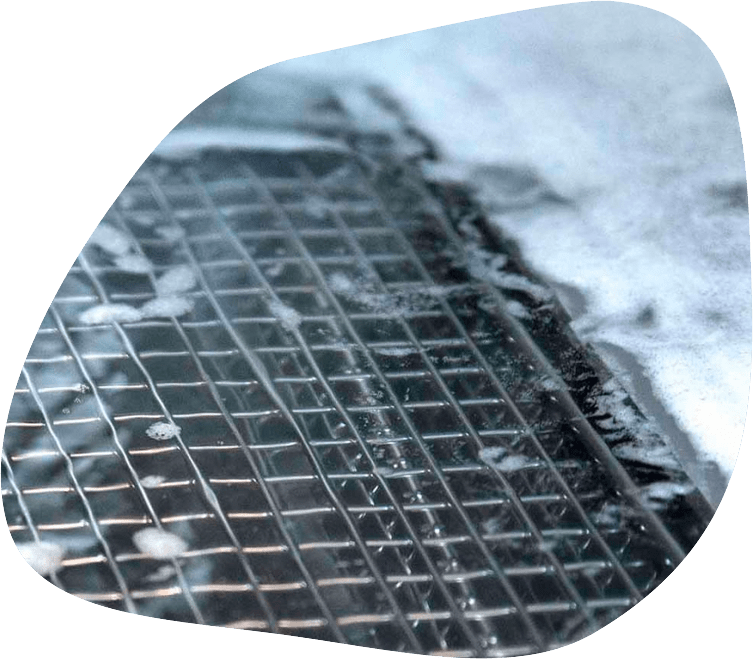

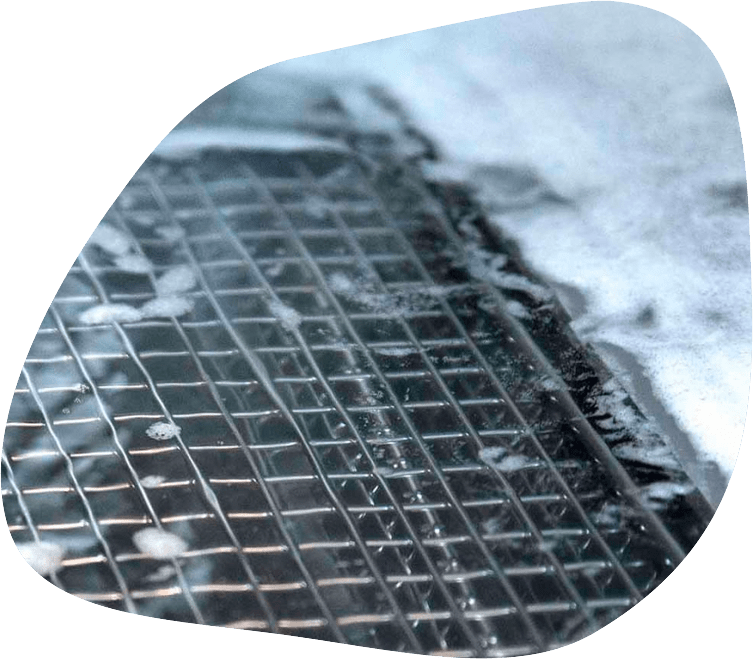

Comes with ultrasonic cleaning, rinsing and drying both as standard and custom systems depending on the task and is designed as a modular tank system where the items are washed in baskets

In certain cases, the task requires us to use solvents with a low flash point below 60°C, which places very strict requirements on the washing system. As a company, you usually want to avoid this, since it places extraordinary demands on both equipment, handling, storage and employees.

But this is not always possible since some tasks can only be solved with solvent or alcohols which form an explosive atmosphere when they evaporate. This can be isopropanol, acetone or other flammable liquids and they are most often used in connection with 3D printing and the pharmaceutical industry.

ATEX washing system with high safety

Since this type of washing system is a necessity to solve a number of tasks in the industry, we have specialized in the supply of this type of equipment, where safety is paramount so that you meet current regulations and ensure your employees the best working environment in connection with work in this type of liquids.

This places a great demand on documentation, installation of equipment and training of the staff, which we can help with, thus we are with you all the way and ensure a safe working environment and clean items all year round.

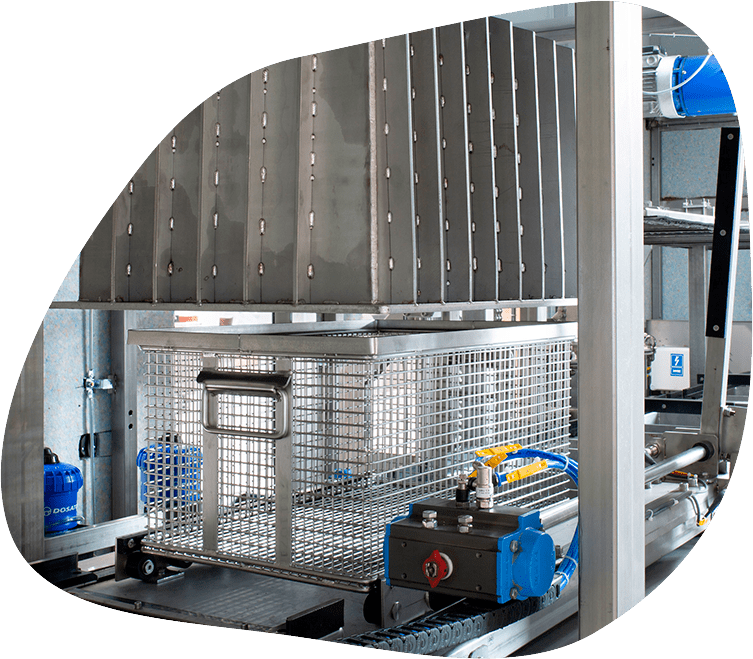

This type of washing system is supplied with ultrasonic cleaning, rinsing and drying both as a standard and special system depending on the task and is designed as a modular tank system where the items are washed in baskets. The solution is also available fully automatically, where a portal moves the baskets between each individual module and the operator only has to pick up and bring the basketem hver enkelt modul og operatøren skal blot hente og bringe kurven.

ATEX washing system

At Anmasi, we design, develop and deliver washing and cleaning technology solutions and services for demanding tasks and industries. We have a wide range of leading standard solutions that cover most needs within industries such as automobiles, aviation, wind power, medicine and healthcare, etc. However, our expertise also enables us to modify existing equipment and design customized solutions for any task.

A parts washer or conveyor washer is used to wash items continuously directly in the production line, so that you avoid handling the items between processing machines and washing facilities. It is indispensable in a mass production of uniform items in connection with punching, turning and similar production methods.

ATEX washing system with Atex zone classification

n certain cases, the task requires the use of solvents with a low flash point of less than 60 degrees, which places very strict requirements on the washing system. As a company, you usually want to avoid this, as it places extraordinarily high demands on both equipment, handling, storage and employees. But this is not always possible, as some tasks can only be solved with solvents or alcohols, which form an explosive atmosphere when they evaporate.

With an atex washing system, you get a solution for explosive liquids with a low flash point, where safety and functionality are the focus.

ATEX washing system for business

Since this type of washing system is a necessity to solve a number of tasks, we have specialized in this type of equipment, where safety is paramount, so that applicable regulations are met and your employees are ensured the best working environment in connection with work with this type of liquids.

This type of washing system is supplied with ultrasonic cleaning, rinsing and drying, both as a standard and special system depending on the task, and is designed as a modular tank system where the items are washed in baskets. The solution is also available as an automatic washing system where a portal moves the baskets between each individual module and the operator only has to pick up and bring the basket.

Contact us today!

If this type of washing system is a necessity in your production, contact us today. We find the right solution for you and of course we install the equipment and train your staff, so we are with you all the way and ensure a safe working environment.

We specialize in custom facilities, and we can therefore also supply a compo cleaner for your production according to your wishes and needs. Call us and we will discuss the various options we can offer you and your production. We look forward to hearing from you!

Anvendelsesområder

Olie- og kølesmøremidler

Vores vaskeanlæg fjerner nemt olie- og kølesmøremidler fra bearbejdede emner, og komponenter som skal vedligeholdes. Vi kan rengøre næsten alle overflader af metaller, plastik, kunststof etc.Tidsintervallet i processen varierer, samt hvilken type kemi vi bruger til den enkelte opgave. Det afhænger af hvilke typer af olier- og kølesmøremidler vi arbejder med, fælles for dem alle er at de rengøres i en vandbaseret løsning, som er enten neutral eller mild alkalisk.Hvilken type af vaskeanlæg og metode afhænger af den specifikke opgave, og bestemmes i dialog med kunden.

Rust

Vi fjerner effektivt korrosion med vores neutrale vandbaserede rustfjerner. Den fjerner både nyt- og gammel rust fra eksempelvis reparationsemner, eller flyvrust på komponenter.Alt dette gøres effektivt med vores neutrale produkt, samtidig med at tage hensyn til omgivelser og arbejdsmiljøet.

Maling

Vi har stor erfaring med at fjerne maling fra komponenter. Vi fjerner typisk maling fra malerkroge, fixturer, ophæng, pumper, pistoler og dyser.Fordelen ved et vaskeanlæg til opgaven, er at i får en lukket proces, hvor man undgår manuel rengøring med kraftige kemikalier, som f.eks. fortynder. I stedet får i et vaskeanlæg med vandbaseret malingsfjerner.Vi kan både fjerne flydende- og hærdet maling, som oftest gøres ved hjælp af en ultralydsrenser.

Epoxy

Vi har stor erfaring med at fjerne både hærdet- og ikke-hærdet epoxy fra emner. Hvilket i mange tilfælde er en svær opgave, uden det rette udstyr. Derfor er det vigtigt at have den rette løsning hvad angår både kemi og vaskeanlæg.Fordelen ved vores løsninger, er at de automatisk og miljøvenligt i en vandbaseret løsning fjerner epoxyen, og tager hensyn til arbejdsmiljøet.Vi har igennem de seneste år, udviklet mange specialløsninger for specielt kunder i vindmølleindustrien til dette formål.

This washing system is offered both with a drain pump, filter system, data transfer, process monitoring and touchscreen, depending on the customer’s needs and documentation requirements.

This washing system is carried out as standard with:

- ATEX ZONE 2 Classification

- Double fan

- Pressure monitoring of nitrogen

- Ultrasonic cleaning