Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

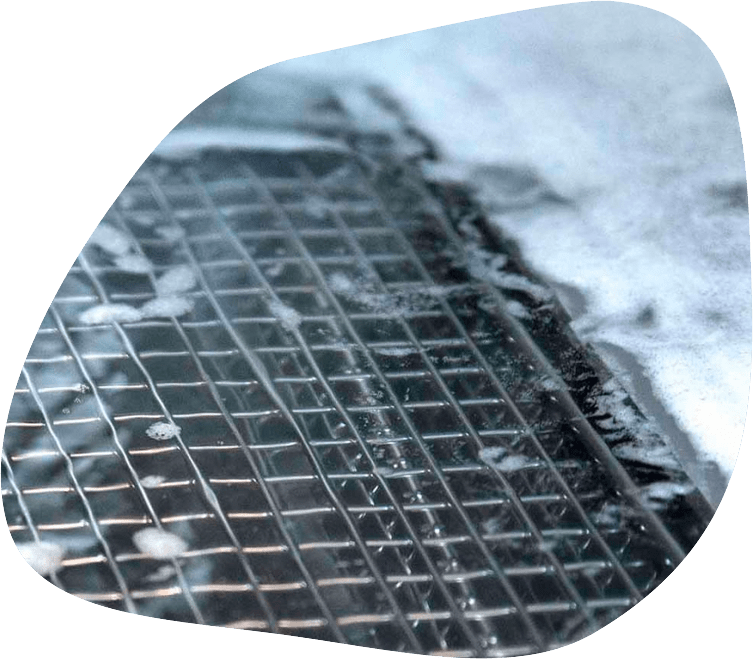

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Beltline – Steel profiles

Understanding of our customers and many years of dialogue resulted in the production of huge washing system for a Russian company that produces extruded steel profiles for the automotive industry, mainly in Germany.

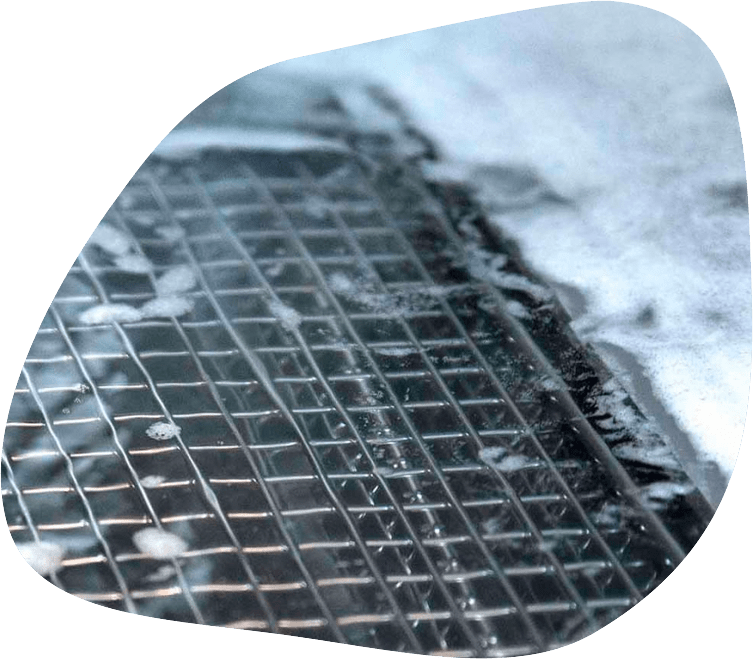

The customer approached us at an exhibition in Germany and was looking for a washing system for his large production of extruded steel profiles in eastern Russia. All the steel profiles were hot contaminated with oil and dirt which had to be removed following a requirement from a major customer.

It was not washing process and rust protextion of the items during transport to Germany, which in this case was the problem, but instead it was the large amount of items and the handling of these through the washing facility which made it a complex task even for experienced companies like us.

The washing facility itself had to handle 6 – 8 different types of steel profiles with varying lengths from 1000 – 6000 mm, which had to be washed, passivated and dried within a short time. Therefore, the washing facility had to process mere than 6 tons of steel per hour around the clock.

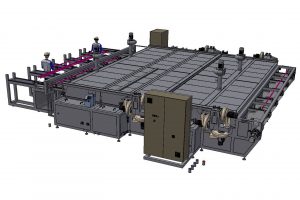

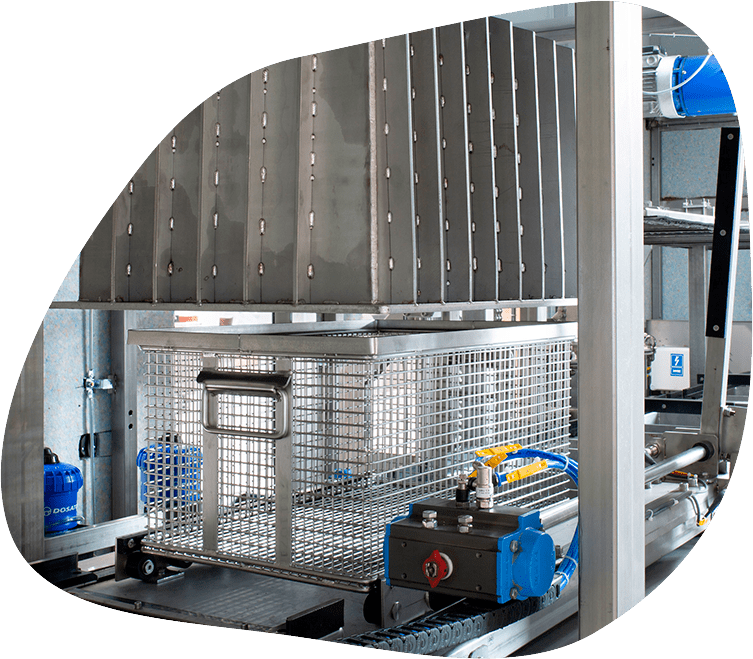

After a long dialogue with various proposed solutions, we found a solution that suited the customer’s production line and we began to design the washing facility based on our conveyor washer with a chain conveyor, but on a very large scale, which ended up being the largest conveyor washer we have ever delivered.

Design, production and installation took less than a year and the washing facility was installed in Russia by our people and in less than a week the customer washing steel profiles. The customer has not experienced any problems since installation, and we have therefore not been in Russia since installation where the washing facility has been running around the clock, which is not always the case in connection with large development projects like this.

Drawing and pictures of the installed cleaning system can be found in the slide above, and you are welcome to contact us for more information about large custom washing systems.

Who uses this product?

- The aviation industryThe aviation industry has high cleanliness requirements and, like the car industry, we work with large series where this type of washing system or ultrasonic cleaner is most often the right solution.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

- AutomotiveThis washing plant is very popular for tasks in the automotive industry and has been developed for both large and small production lines, depending on your needs.

After installation, the washing facility filled more than 120 square meters.

More than 6,000 kg of steel are washed per hours around the clock, all year round at the factory.

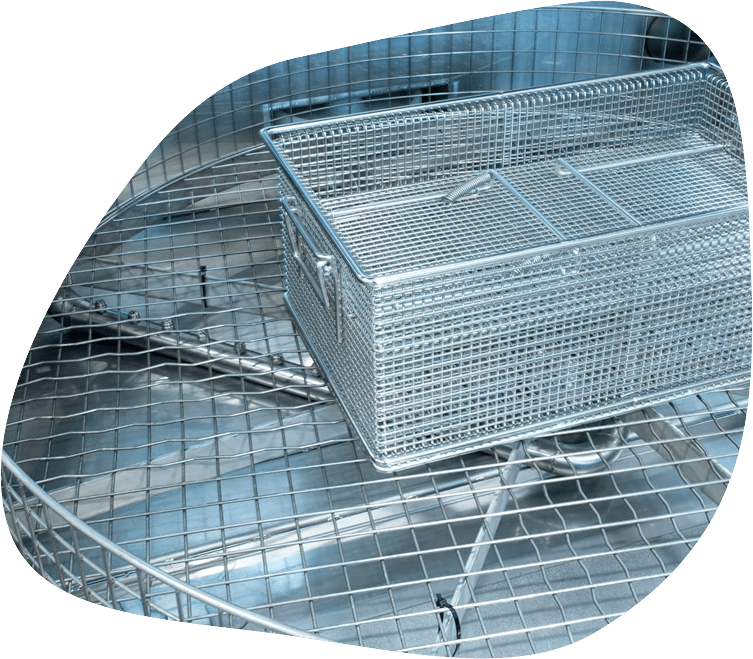

Ultrasonic cleaning, rinsing, rust protection/passivation and drying of the items within a few minutes.

The washing system handles more than 6 different items with different geometry, thickness and length.

| Type | Description |

| Part type | Extruded steel profiles |

| Contamination | Oil, dirt |

| Part size (max.) | Ø100×6000 mm |

| Part weight (max.) | 25,0 kg |

| Machine dimensions | 9000x12000x1800 mm |

| Zones | 4 |

| Power supply | 160 A |