Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

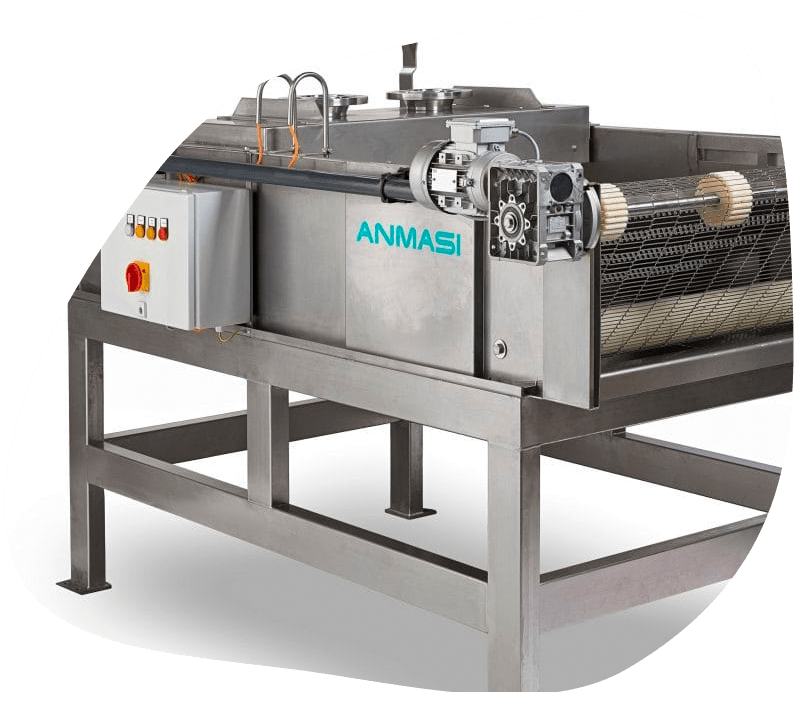

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

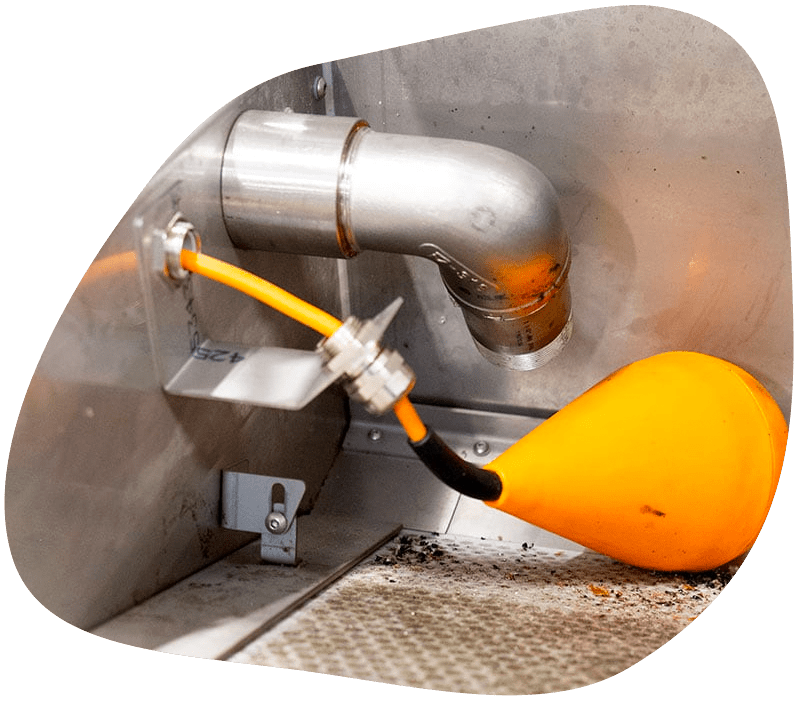

Oil separator

Innovative high-quality oil separator produced in Denmark for removing free oils from the process fluid and is suitable for washing facilities, processing machines and similar.

Our oil separator ensures the best conditions for your process fluid and effectively removes free oil via the section head, which is placed in the tank and operates with an in-house developed electric piston pump. The solution means you as a customer avoid pneumatic pumps or centrifugal pumps which mixes the liquid and therefore negatively affect the natural separation of free oil. The oil separator is available in two sizes with 2 or 4 separation chambers to gently separate the oils.

Applications:

- Washing machines

- Processing Machines

- Liquid tanks

- Waste water management

See the oil separator in action on this video of a filter system:

- WastewaterOur filter systems are used for the treatment of waste water in the municipal sector and are ideal for pre-treatment of waste water and process fluids before ultrafiltration etc.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

The oilskimmer has a strong construction made of stainless steel grade: AISI 304.

The specially developed piston pump ensures high efficiency removal of oils using a suction head in the tank uni.

The specially developed piston pump ensures high efficiency removal of oils using a suction head in the tank unit.

The oilseparator has a simple design which makes its very user- and maintenance friendly.

The oilseparator is manufactured according to the European machine directive.

Compact and flexible solution which can be used stationary and as a mobile unit. The oilseparator only needs a single-phase plug.

The efficient separation ensures that your process fluids and oils are being separated completely during the process.

The oilseparator from ensures continuous draining of oils around-the-clock.

Efficient separation of oils extends the life-cycle of the process fluids and lowers costs.

Technical data

| Model | OS-S2 | OS-Q2 |

| Flow capacity | 120 l/hour | 180 l/hour |

| Separation chambers | 2 | 4 |

| Power supply | 220/240V, 50 hz. | 3×230/400V, 50 hz. |

| Length | 305 mm | 500 mm |

| Width | 260 mm | 600 mm |

| Height | 400 mm | 470 mm |

| Weight | 7 kg | 18 kg |