Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

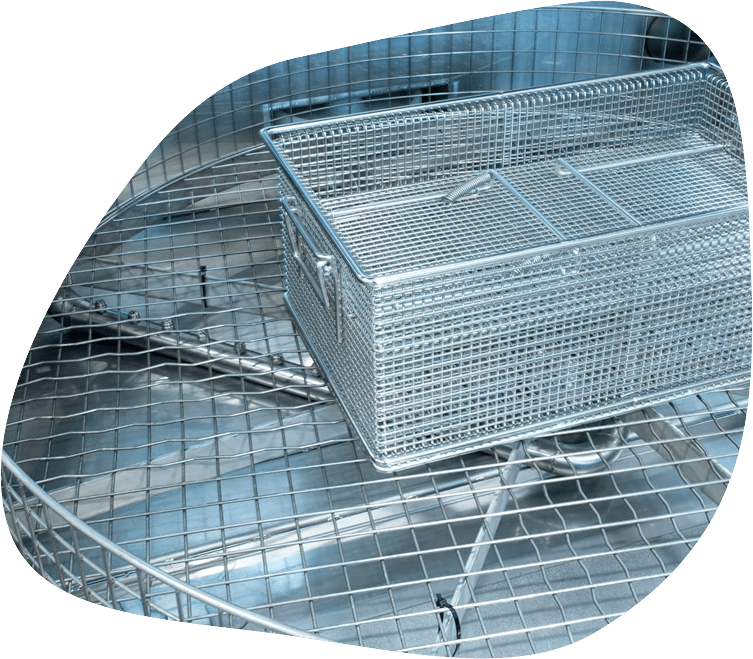

Ultrasonic cleaner

Your expert in standard and special solutions for industry, food and the pharmaceutical industry

All cleaning systems in this category uses ultrasonic cleaning in connection with washing the parts, and are also offered in combination with flushing and turbulence tanks. In an ultrasonic cleaner, we are using ultrasonic waves with a frequency of between 21.5 – 130 kHz to clean parts.

These ultrasonic waves form cavitation bubbles in the liquid which remove the impurities from the surface upon contact with the object. Ultrasonic cleaning is used both with solvents and water-based chemistry to remove, among other things, cooling lubricants, oil, wax, soot, dust, rust, blood, paint, varnish, lime, bitumen etc.

Ultrasonic cleaner with the latest technology

The technology is very suitable for complex and sensitive subjects that require gentle treatment. This can be, for example, a polished stainless surface or aluminium. Ultrasonic cleaning is preferred when we work with burnt-on and hard dirt that has settled on the surface of the items in connection with the production or maintenance of components.

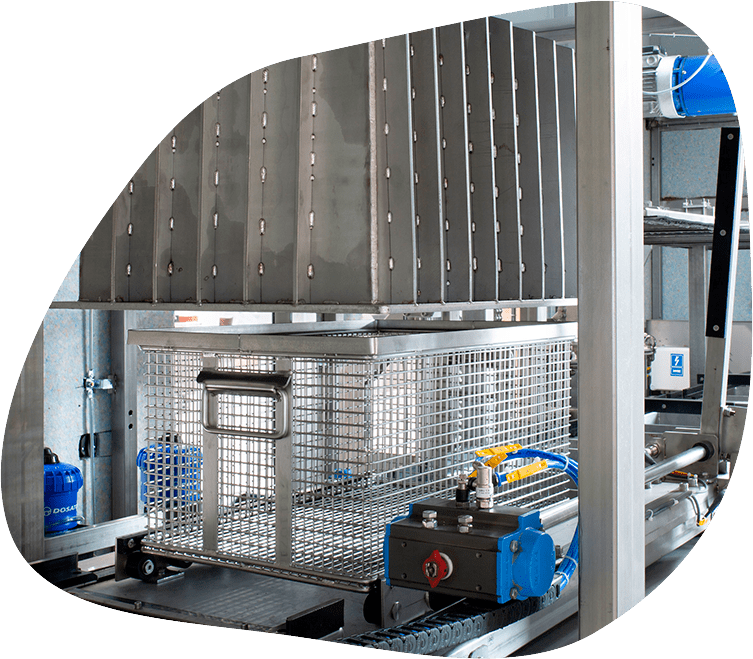

An ultrasonic cleaner consists of a set of ultrasonic transducers which are mounted either in the bottom or on the sides of the tub, depending on the task. These ultrasonic transducers form the ultrasonic waves when they receive voltage from the ultrasonic generator and these components are different depending on the task. Because it is the task that determines which ultrasound frequency is used for the task and can be seen below:

Ultrasound frequency

25 kHz = Large bubbles, powerful ultrasonic effect, less gentle, suitable for large objects and hard surfaces.

40 kHz = Good ultrasonic effect, gentle and suitable for many surfaces and types of items. The bubbles are of medium size and are good for smaller items.

100 kHz = Small bubbles, low ultrasonic power, particularly suitable for very sensitive items, the bubbles are small and suitable for very small holes.

In addition to the frequency, the number of watts per liter of liquid is also a lot to say, since if we don’t create enough cavitation in the liquid then you won’t achieve the desired result. The ultrasonic power in watts depends on the task, but as a general rule, the ultrasonic cleaner must have a nominal power of around 10 watts per liters so that you as a user achieve the desired washing result.

What is ultrasonic cleaning?

Ultrasonic cleaning is a washing process where ultrasonic waves with a frequency of 21.5-130 kHz are used to wash the objects. These ultrasonic waves form cavitation bubbles in the liquid which remove the impurities in the surface upon contact with the object. Ultrasonic cleaning is used both with solvents and water-based chemistry to remove cooling lubricants, oil, wax, soot, dust, rust, blood, paint, varnish, lime, bitumen, etc.

The perfect business solution

An ultrasonic cleaner is the perfect solution for businesses, as the technology is suitable for complex and sensitive items that require gentle treatment. This can e.g. be a polished stainless surface or aluminium.

Ultrasonic cleaning is preferable when working with stuck-on and hard dirt that has settled on the surface of the items in connection with the production or maintenance of components.

Our washing system is particularly suitable for oil and cooling lubricants, as they easily remove these from machined parts and components that need to be maintained. They can clean almost all surfaces of metals, plastics, plastics, etc.If you need to remove rust, our products effectively remove corrosion with our neutral water-based rust removers. It removes both new and old rust from, for example, repair items or aircraft rust on components.

Other areas of application include paint, epoxy, 3D printing, rubber, thermal deburring and wire sparking. The advantage of a washing plant for your task is that you get a closed process, which avoids manual cleaning with strong chemicals. Instead, you get a washing system with specially developed chemicals that take the environment into account.

Contact us today

If you are curious about how one of our ultrasonic cleaners can create value in your business, do not hesitate to contact us – we can help you find the right solution.

The type of washing system and method depends on the specific task and is determined in dialogue with you. We are experts and we offer complete solutions and take care of the entire process around design, production, installation and servicing of your ultrasonic cleaner.

Many years of experience

We have many years of experience in industrial washing and cleaning technology. We have 30 years of experience in designing, developing and delivering washing and cleaning technology solutions and services for demanding tasks and industries.

Our experts ensure efficient installation and implementation of your solution, and our extensive service and accessory program ensures that it is kept running.

We are ready to help you

Call now and talk to one of our experts about which solution is right for your business. We look forward to hearing from you and finding a way in which we can add value to your business.

Anvendelsesområder

Olie- og kølesmøremidler

Vores vaskeanlæg fjerner nemt olie- og kølesmøremidler fra bearbejdede emner, og komponenter som skal vedligeholdes. Vi kan rengøre næsten alle overflader af metaller, plastik, kunststof etc.Tidsintervallet i processen varierer, samt hvilken type kemi vi bruger til den enkelte opgave. Det afhænger af hvilke typer af olier- og kølesmøremidler vi arbejder med, fælles for dem alle er at de rengøres i en vandbaseret løsning, som er enten neutral eller mild alkalisk.Hvilken type af vaskeanlæg og metode afhænger af den specifikke opgave, og bestemmes i dialog med kunden.

Rust

Vi fjerner effektivt korrosion med vores neutrale vandbaserede rustfjerner. Den fjerner både nyt- og gammel rust fra eksempelvis reparationsemner, eller flyvrust på komponenter.Alt dette gøres effektivt med vores neutrale produkt, samtidig med at tage hensyn til omgivelser og arbejdsmiljøet.

Maling

Vi har stor erfaring med at fjerne maling fra komponenter. Vi fjerner typisk maling fra malerkroge, fixturer, ophæng, pumper, pistoler og dyser.Fordelen ved et vaskeanlæg til opgaven, er at i får en lukket proces, hvor man undgår manuel rengøring med kraftige kemikalier, som f.eks. fortynder. I stedet får i et vaskeanlæg med vandbaseret malingsfjerner.Vi kan både fjerne flydende- og hærdet maling, som oftest gøres ved hjælp af en ultralydsrenser.

Epoxy

Vi har stor erfaring med at fjerne både hærdet- og ikke-hærdet epoxy fra emner. Hvilket i mange tilfælde er en svær opgave, uden det rette udstyr. Derfor er det vigtigt at have den rette løsning hvad angår både kemi og vaskeanlæg.Fordelen ved vores løsninger, er at de automatisk og miljøvenligt i en vandbaseret løsning fjerner epoxyen, og tager hensyn til arbejdsmiljøet.Vi har igennem de seneste år, udviklet mange specialløsninger for specielt kunder i vindmølleindustrien til dette formål.

ULTRASONIC

Standard modules:

- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Spraywashers

- Flushing tank with turbulence

- Hot air drying

- Vacuum drying