Surface treatment

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

Solvents and alcohol

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

For our customers, we optimize within degreasing, dust removal and temporary corrosion protection.

Special products

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

For our customers, we optimize within degreasing, dust removal and temporary corrosion protection.

Paint & composite

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

For our customers, we optimize within degreasing, dust removal and temporary corrosion protection.

Repair & maintenance

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

For our customers, we optimize within degreasing, dust removal and temporary corrosion protection.

Degreasing & passivation

Fast delivery time and better quality are the parameters on which our customers are measured, at the same time with consideration for the environment and reduction of CO2. With our professional laboratory, experience and knowledge, we work for our customers and a better environment.

For our customers, we optimize within degreasing, dust removal and temporary corrosion protection.

Epoxy remover

It may seem almost impossible to remove epoxy, but we have found a searies of mild, water-based epoxy removers that work perfectly in our washing facilities.

These products remove both epoxy, paint and glue, which is perticularly useful in, for expample, wind turbine production and other indstries that work with moulds.

Over the last 10 years we have become very specialized in industrial cleaning equipment for removing epoxy resins from parts. The journey started because one of our major customers was looking for a solution to replace acetone in the production, where it was mainly used to clean production equipment.

This request resulted in Anmasi Group starting to develop their first standard solutions for cleaning off epoxy resins from parts using non-hazardous chemicals protecting both works and the environment. Because of our customers we have today supplied more than 100 cleaning systems over 10 years for removing epoxy resins to both small and large customers all over the world.

The experience means we have worked with a wide range of epoxy resins, and therefor knows which cleaning technologies and chemicals we need for the various resins. This also means today we have solutions for both uncured and cured epoxy.

Epoxy resin state

We have solutions designed for epoxy in different states, without using strong solvents such as acetone:

- Uncured epoxy (liquid)

- Semi-cured epoxy

- Fully cured epoxy (hard surface)

Application

We have designed systems for many different applications, where epoxy resins are involved, and below is mentioned some of our largest markets:

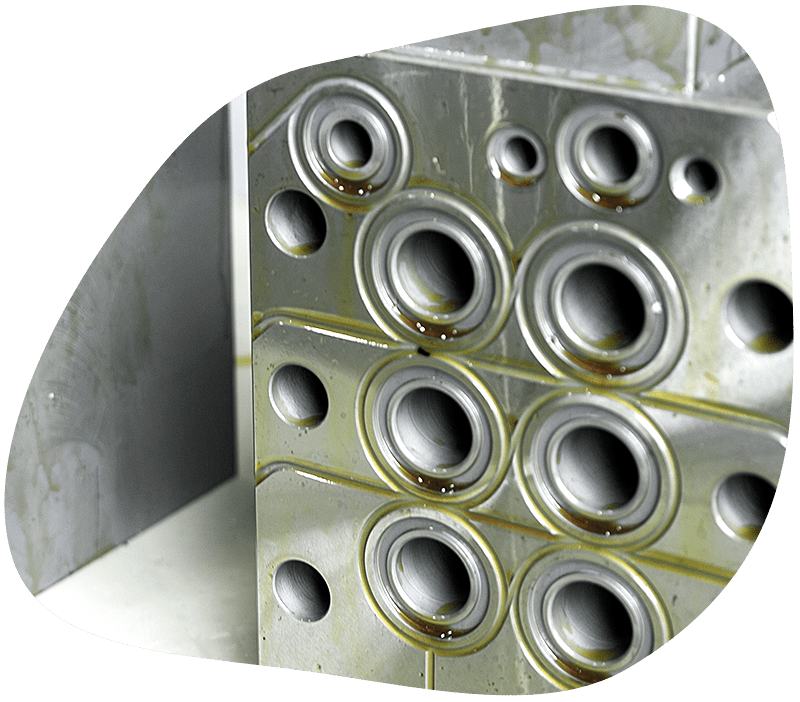

- Production equipment – wind power and offshore industry

- Filament winding machines

- Manual tools such as spatulas, buckets, covers etc.

- Equipment inside dispensing systems and mixers for epoxy resins

- Tools and hooks used in wet paint workshops using epoxy-based resins.

Keep in mind that with our mild chemicals for removing epoxy resins we can usually work on all metals and most types of plastic parts without causing any damages which is one of the reasons why our solutions are successful.

If you want to learn more about our solutions for removing epoxy resins from parts and production equipment, then please contact us on +45 76 50 02 32 or sales@anmasi.dk.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

We are here to sell you chemicals. We are here to ensure that you use the right chemicals in your washing system so that you can achieve the best washing results and lowes chemical consumption.

Basically, it's about focusing on the process rather than just the product, because we look at chemicals and washing facilities as a single related entity.