Ultrasonic cleaner

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Spraywashers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Conveyor washers

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Rotating basket washer

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Customized facilities

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

ATEX system

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

Alcohol washers

Discover some of the market's most efficient and energy-friendly alcohol washers, which are offered both as standard and special systems

CLICK ON ONE OF THE CATEGORIES TO READ MORE!

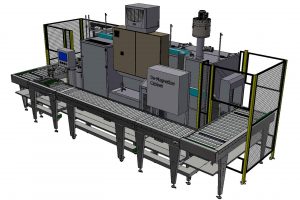

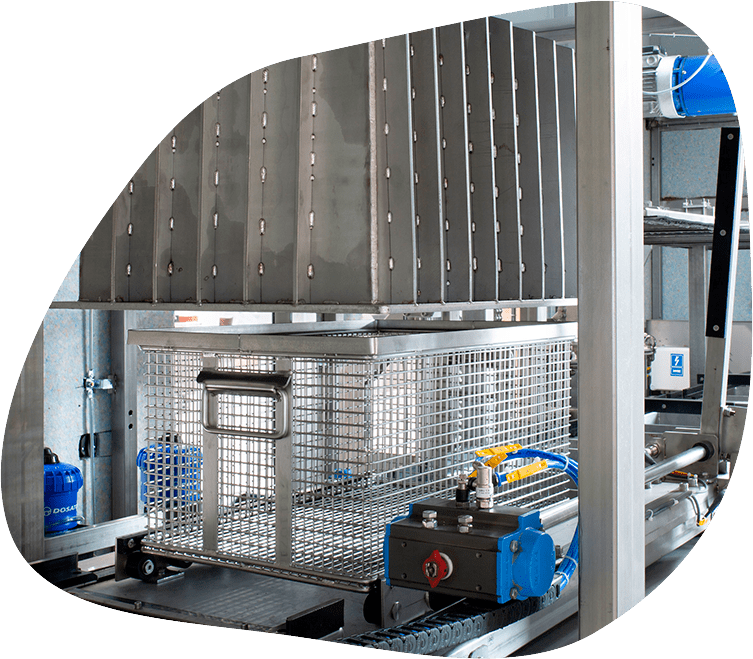

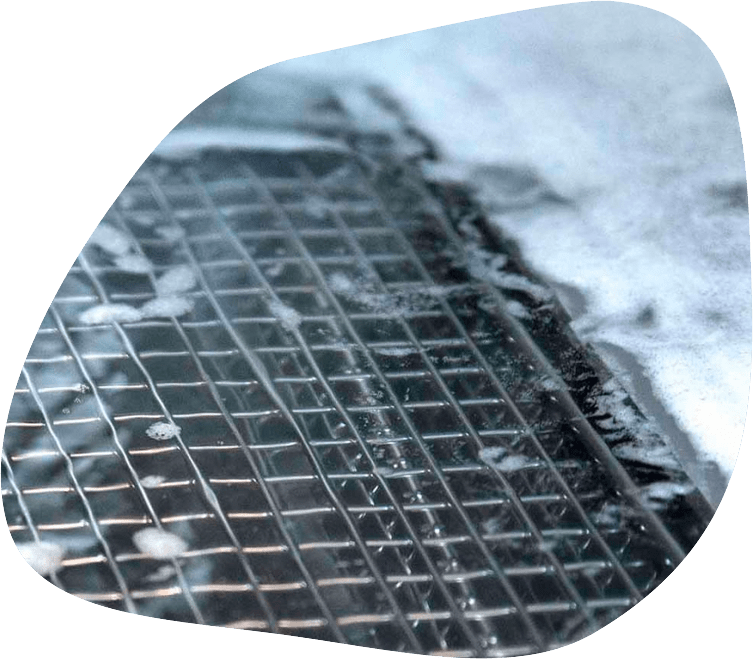

Beltline – Stamping tools

Flexibility, expericance and fast delivery resulted in the manufacturing of two large cleaning systems for one of the largest companies in the automotive industry worldwide, and they were delivered in just 16 weeks, customized to the customer’s specification.

The customer was looking for flexible and solution-oriented manufacturer of a cleaning system for cleaning stamping tools for their factories in the Netherlands and Vietnam. This is how ANMASI came into the picture with oir flexible approach to washing systems we develop both with ultrasonic cleaning and spray washing, which was a requirement for the customer and since the number of companies with comprehensive experience in both areas like ANMASI is scarce, we were quickly chosen.

The stamping tools had to be washed in 2 parts of 200 kg very 15 minutes, which placed great demands on just the cleaning system but also on the handling of the tools as they were very sensitive due to high demands on the precision in connection with punching this type of items.

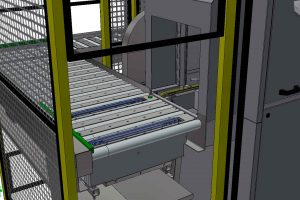

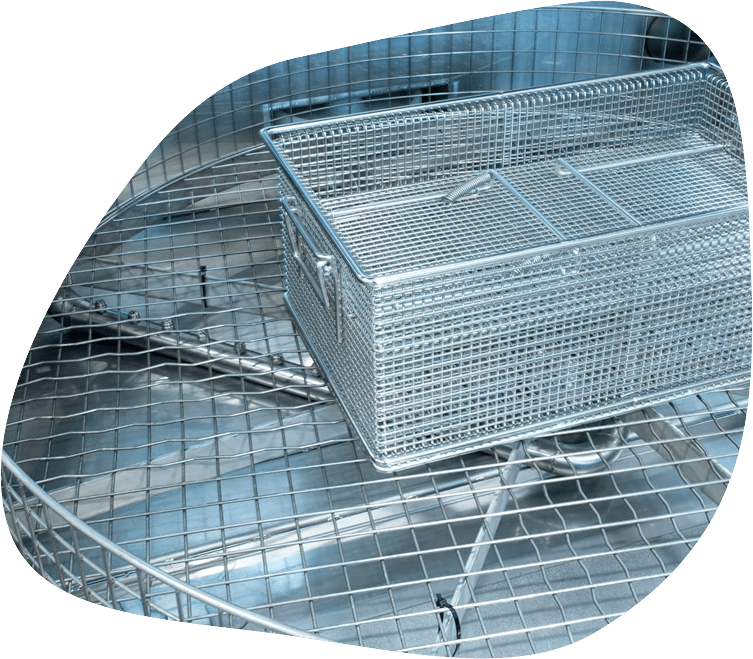

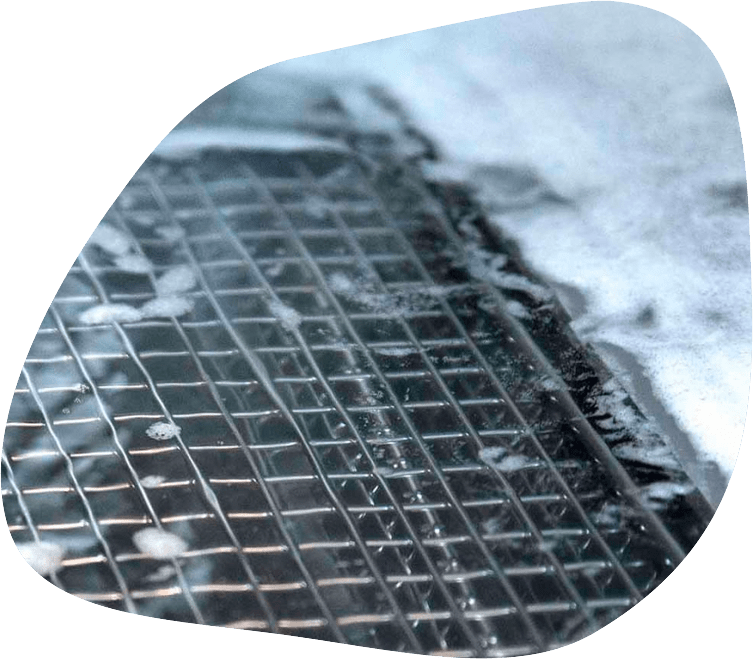

Therefore, the task includes both a cleaning system with ultrasonic cleaning, rinsing and drying as well as a transport system with ergonomic fixtures for handling developed especially for the task where we wash the tools around the clock.

This meant that we delivered a cleaning system that was integrated into their entire workshop, where each individual workstation was connected to a conveyor belt that automatically delivered stamping tools to the cleaning system after it has been separated, and returns them after the washing process.

It also meant that the employees at the 6-8 workplaces, no longer had to handle the tools with a crane around the workshops when they had to be washed or similar, as everything worked automatically. In addition, we installed a “demagnitizer” at the inlet of the cleaning system to loosen all the metal shavings before washing, thus increasing the throughput time considerably and ensuring that the tools were completly free of shavings after washing.

The drawings and pictures of the cleaning system can be found below and due to agreements with the customer, it is not possible to show pictures or drawings of the completed cleaning system.

Who uses this product?

- The aviation industryThe aviation industry has high cleanliness requirements and, like the car industry, we work with large series where this type of washing system or ultrasonic cleaner is most often the right solution.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

- AutomotiveThis washing plant is very popular for tasks in the automotive industry and has been developed for both large and small production lines, depending on your needs.

Tailored cleaning process combining several technologies to achieve the best cleaning result

Stamping tools with a weight of 200 kg every 15-minute around-the-clock

Due to our flexible organization we were able to manufacture the system within just 16 weeks, to meet customer requirements.

Project including several parts such as conveyor system, cleaning system, drying module, transport trays and integrated demagnetizer.

| Type | Description |

| Part type | Stamping tools |

| Contamination | Oil, Metal particle |

| Part size (max.) | 700x500x400 mm |

| Part weight (max.) | 250 kg |

| Machine dimension | 6500x2300x2800 mm |

| Zones | 3 |

| Power supply | 160 A |