Oil separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Reverse osmosis

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

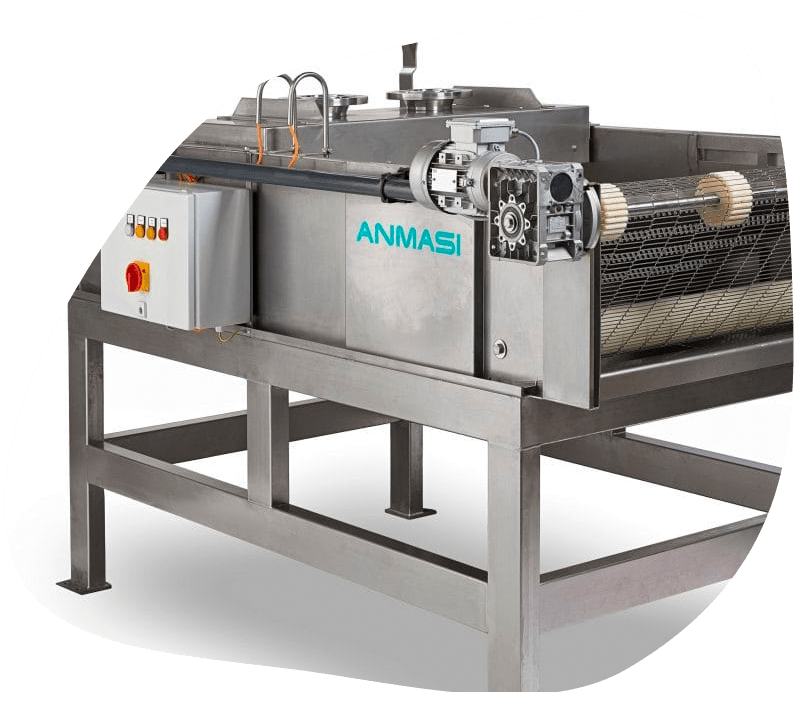

Magnetic Separator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Evaporator

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Filtration systems

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

Ultrafiltration

Your expert in total solutions for the metal industry, plastics industry, food and pharmaceuticals.

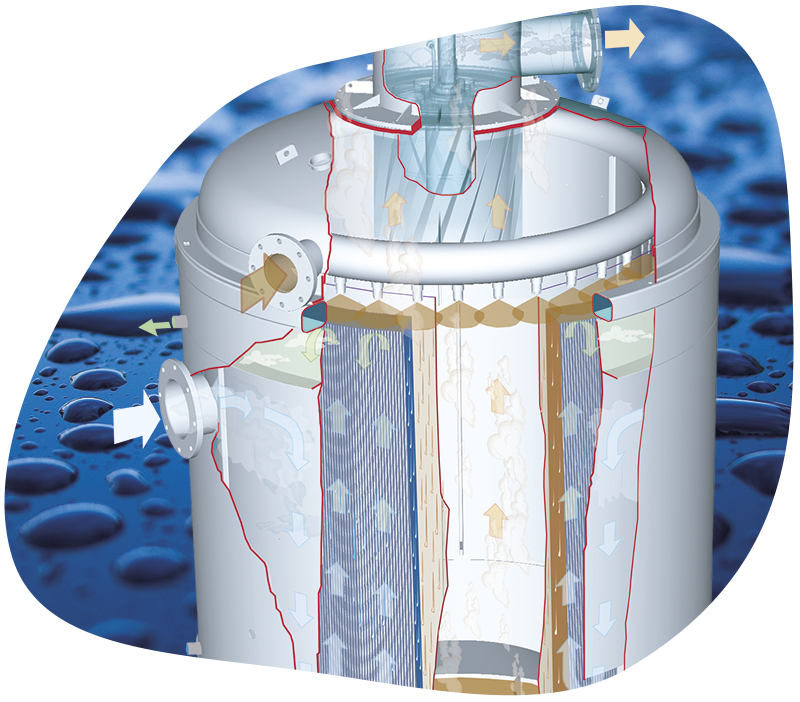

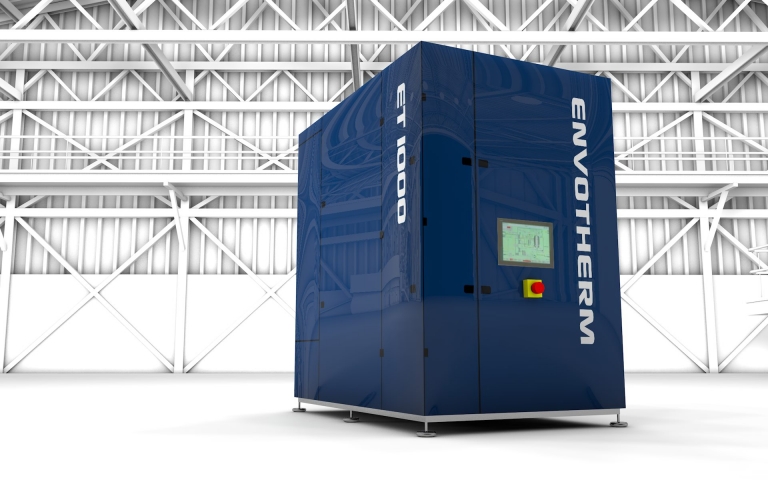

Envotherm ZLD

Less waste and more clean water

- Means minimizing costs

- Reduces the amount of wastewater by 95-99%

- Reduces CO2 emissions

- Recycle resources, in some cases, resources that are excreted from the water can be recycled

The technology behind it

Heat exchanger – the ingenuity behind the system is the reuse of the outgoing steam to heat the incoming wastewater. This achieves a reduction in energy consumption by up to 66% compared to competitors. The evaporation process – Concentrated distilled, ready for disposal without further treatment.

Increased amount of clean water – the system significantly increases the amount of clean water – ready for reuse in your production without additional costs for treatment. Reduced disposal costs – The final liquor goes through a refined distillation process which significantly reduces disposal costs. Costs that can only be expected to increase in the coming years.

ZLD – ZLD stands for Zero liquid Discharge, which is a term for a wastewater technology in which all contaminants are sorted from the water and no water is wasted. Instead, the water can be reused again and again.

What is ZLD?

ZLD stands for Zero liquid Discharge and is the term for wastewater technology in which all contaminants are sorted from the water and no water is wasted. Instead, the water can be reused again and again. By using a ZLD system, you optimize your wastewater treatment and save resources.

There are many different advantages of using a ZLD technology, the most important of which are:

Reduced waste

With Envotherm’s E•MVR technology, you can reduce the amount of wastewater by 95-99%

Reduction of CO2 emissions

The wastewater incineration process is extremely CO2-intensive. With the reduced amount of wastewater significantly less CO2 is therefore also generated from combustion. In addition, transport to and from incinerators is also minimized, and the transport-related CO2 emission will therefore also be minimized.

Recycling of resources

In some cases, resources separated from the water can be recycled. This is, for example, relevant if your company processes precious metals such as gold or silver.

How can E•MVR use so much less energy?

E•MVR, Envotherm’s patented technology for treating wastewater, stands for Envotherm Mechanical Vapor Recompression, and is an evaporation technology for treating industrial wastewater. E•MVR is both the name of our technology and the term for process where the energy from the steam, which comes from the outgoing distillate is reused to heat incoming wastewater.

Recycling of heat

Compared to e.g., vacuum evaporation, where wastewater is fed into a vacuum chamber in batches, wastewater is continuously fed into the evaporation chamber with E•MVR. Therefore, when using vacuum evaporation, you must use energy to start the pump/compressor every time a new batch is fed into the chamber. This energy cannot be recycled, while the excess heat from the outgoing batch is not sufficient to have significant effect on the heating of the next batch. Therefore, there is a high energy loss during vacuum evaporation.

When you use E•MVR, the compressor runs continuously, and the heat never leaves the heating process. Since the evaporation chamber is connected to the preheat exchanger, this means that only minimal amount of energy must be added to maintain the evaporation process in the evaporation facility.

- WastewaterOur filter systems are used for the treatment of waste water in the municipal sector and are ideal for pre-treatment of waste water and process fluids before ultrafiltration etc.

- Plastic industrySuitable for companies in the processing of plastic parts, where you often meet the same requirements as in the metal industry and oil, cooling lubricants and plastic shavings are not accepted at the same time as high demands on the surface.

- Metal industryThis solution is suitable for companies within turning, milling, stamping and other processing in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal shavings and ensure a consistently high quality in the surface.

Reduce your amount of wastewater by up to 99% in the company

The solution can be tailored so that you get the desired quality and conductivity of distillate.

Supplied complete with installation, start-up and training of your employees.

The equipment is insulated to reduce both heat and noise nuisance.

Removes virtually all impurities from the water, such as heavy metals, chemicals, solid particles and the like.

Distillate is so pure that it can be reused in production, so you don't need to dispose of the liquid.

The equipment is fully automatic and takes care of itself as long as the operator ensures that any consumables are present.

You get constant monitoring with a service agreement from us, where we can constantly monitor the operating status of your equipment and provide information about any problems.

Technical data

Heat exchanger

By reusing the outgoing steam to heat the incoming wastewater, a facility from Envotherm need 66% less energy than a similar facility from competing technologies.

Evaporation process

With the evaporation technology from Envotherm, you get completely clean distillate that can be reused as soft water in your production, and discharged directly to the sewer

Absorb

Our patented absorber removes waste substances in your process water by separating water vapor and non-water vapor. The clean water vapor continues in the process, while the waste is continuously fedback for further evaporation.

Defoamer

The mechanical defoamer breaks foam bubles in the heat exchange evaporator, which then prevents chemicals from following the steam further during process.